DKM are professional in Preform Making Machine,DKM has always stood at the forefront of technological revolution and the development of the times, and is committed to leading the development trend of injection molding industry in China and even in the world.We have many experienced engineers,providing solutions for your preform production.DKM can provide customers with preform making equipment and better performance, and higher degree of automation, which enables customers to produce efficiently and stably.

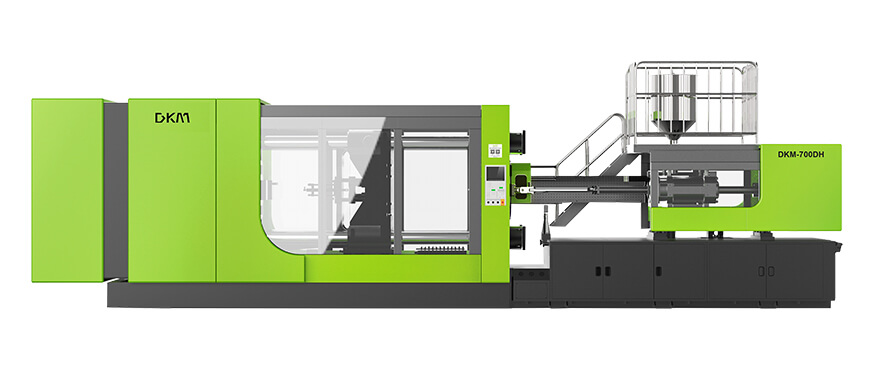

The water preform molding is first used our special DKM PET injection molding machine, which has a faster cycle and energy saving effect. After injection molding, it is blown with a blow molding machine,DKM fully automatic blow molding machine is suitable for all types of mineral water bottles.The production of the assembly line provides solutions for your mineral water bottles.

The oil preform moling is less screw than the water preform, and it is generally a large capacity of 5-30L.The oil preform used our special DKM PET injection molding machine, which has a faster cycle and energy saving effect.After the injection moling,DKM use the boling machine with one cavity,having the advantages of low scrap rate,high speed,stable performance,and easy operation etc.

DKM preform can follow project professionally and control quality strictly,providing engineers' on site assistance of commissioning and training at customers' companies.Providing comprehensive documents,such as installation drawings, operation&maintenance manuals,and technical materials.DKM responds quickly to customer requirements and provides customers with satisfactory service.