DKM

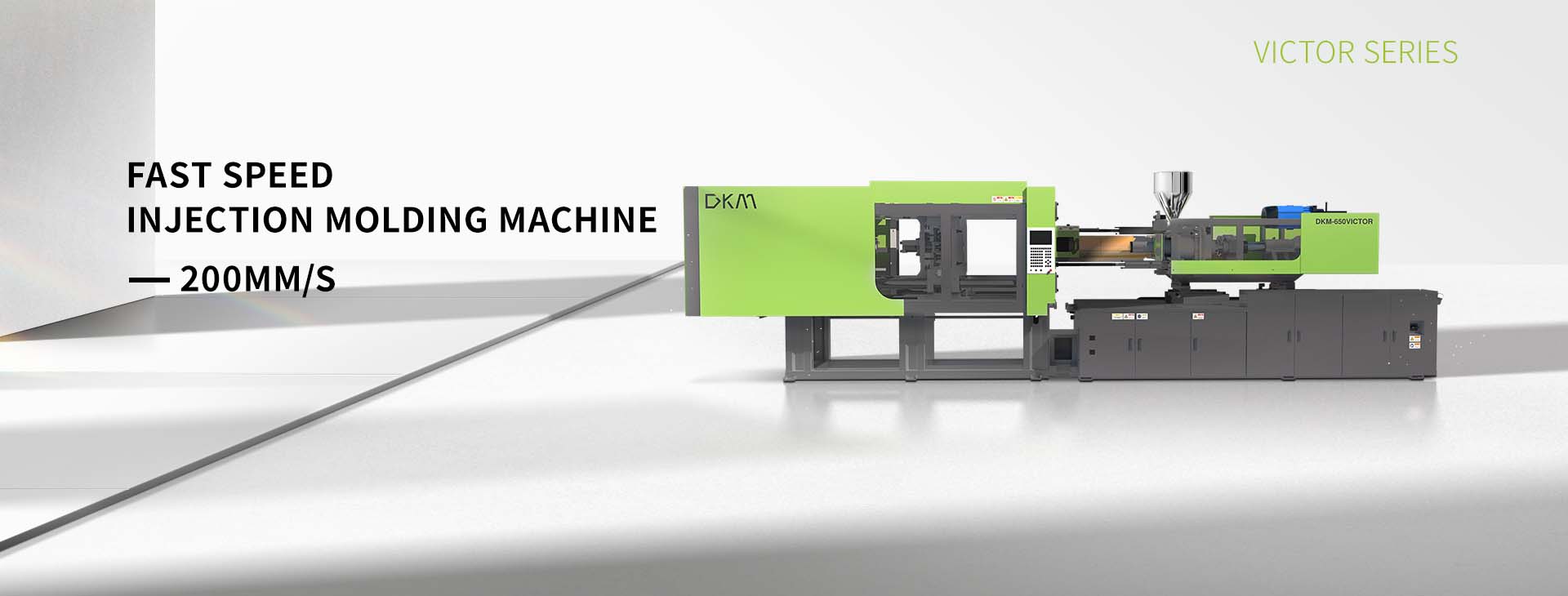

Fast Speed Injection Molding Machine

200mm/s

DKM victor series of fast speed injection molding machines are designed to improve molding quality and eficiency, with an injection speed of 200 mm/s. Fast-speed iniection has been a maior trend in iniection molding process, While ensuring precision molding, the Victor seriesshortens molding cycles (by 25-50%, depending on mold and plastic parts’characteristics),signiicanly improves ROl rates, reduces energyconsumotion, and sienificantly increases production capacity, This alows users to win in the iercely competitive market, heling DkM' s usersbecome the VlCTOR.

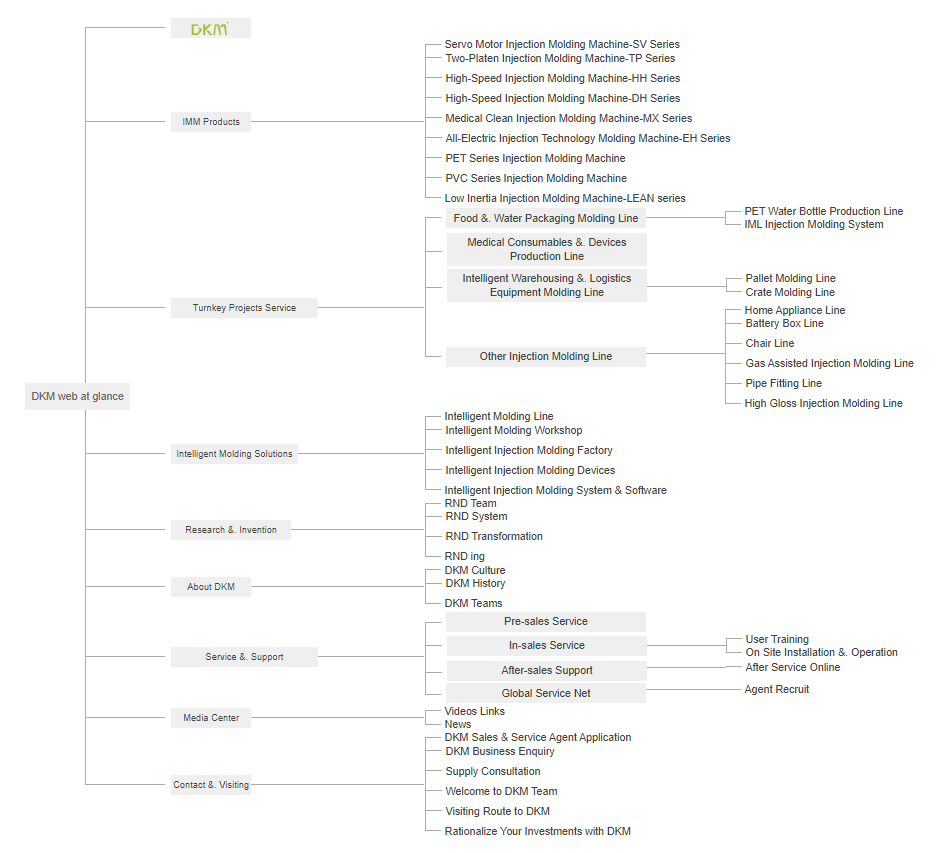

Comparison Between

Fast-Speed Injection Molding Machines

and Other Series Machines

Feature

Ordinary Machine

SV Series

SV Series

Fast-speed Machine

Victor Series

Victor Series

High-speed Machine

DFS Series

DFS Series

Injection Speed Range

0-100mm/s

100-200mm/s

>300mm/s

Cycle Time

Standard

Fast

Faster

Energy Consumption

Low

Low

Standard

Cost

Low

Medium-Low

High

● Ordinary injection molding machines operate at speeds of ≤100mm/s, resulting in slow melt filling and premature solidification in the mold cavity corners, making it difficult to transmit holding pressure. To prevent localized shrinkage marks, increased holding pressure is often required, increasing product weight. This leads to mould cavity depression and parting surface damage caused by prolonged localized pressure in the mold. This slow-filling injection method, even with increased holding pressure, has little effect on addressing shrinkage marks; the shrinkage marks remain, significantly increasing the production’s defect rate.

● Fast-speed machines, however, boast high injection speeds of 200mm/s, shorten filling time by 50%, keeping the melt molten throughout the entire process. The seamless transition between injection and holding pressure allows for easy pressure retention and simultaneous cooling of the melt in the cavity. The reduced cooling time ensures consistent stress within the part, significantly shortening production cycles and improving efficiency.

● Furthermore, fast-speed injection molding machines offer significantly lower costs and energy consumption than high-speed injection molding machines, making them an extremely cost-effective choice.

Core Advantages

Reduced Molding Cycle Time by 25-50%

Injection Filling Time Reduced by ≥50%

Leveraging high-speed screw advancement technology in the fast-speed machine, the injection speed is significantly increased, leading to a substantial reduction in melt material filling time.

Holding Pressure Time Reduced by ≈20%

The thicker melt core layer formed by high-speed filling enhances the melt's shrinkage compensation flowability, effectively reducing holding pressure and duration.

Simultaneous optimization of cooling efficiency

The end-stage melt enters the cooling stage earlier, shortening the total cooling time by 50%.

100% increase in mold opening and closing speed

The medium-speed machine utilizes proportional valves and differential mold clamping technology, doubling the mold opening and closing speed compared to ordinary injection molding machines.

Significantly Reduced Defect Rate

Eliminate surface sink marks

Homogeneous melt and efficient pressure holding significantly reduce the risk of shrinkage defects, improve the density balance of molded plastic products, reduce internal stress of products, and avoid unnecessary increase in material volume.

Suppression of Flash Defects

The substantial reduction in holding pressure minimizes the likelihood of flash formation at the source.

Energy-Efficient, High-Quality, and Cost-Effective Production

Energy Savings Over 20%

The shortened molding cycle leads to significant energy reduction.

Energy Savings from Holding Pressure Reduction of 5%

The decreased holding pressure and duration further lower energy consumption.

Quality Improvement and Increased Efficiency

Higher finished product rates and increased output per unit time achieve high-quality, low-cost, and efficient production

Structural Performance

Power

Meeting Diverse Production Scenario Demands

Equipped with a robust power system, the machine adapts to a wider range of molding processes and material types, comprehensively addressing complex and variable production needs while enhancing adaptability and application flexibility.

Speed

1.Rapid cavity filling effectively reduces product stress and significantly increases yield rates.

2.Standard proportional valves enable swift and stable mold opening/closing, shortening cycle times.

3.High-performance plasticizing components ensure fast and homogeneous melting.

Productivity

Overall Output Increased by 25-50%

Through structural optimization and system upgrades, operational efficiency is substantially improved. While guaranteeing product quality, output per unit time surges significantly, achieving up to 25-50% higher overall productivity to empower efficient manufacturing.

Energy Efficiency

1.Electric pre-plasticizing enables simultaneous plasticizing functions. Plasticizing speed and quality are enhanced while overall energy efficiency improves by 20%–30%, drastically reducing energy consumption and supporting green manufacturing.

2.Infrared heating bands minimize thermal loss, boost energy utilization, further reduce overall energy consumption, and decrease workshop heat emissions for an optimized production environment.

Application Range

All plastic products with a wall thickness >0.5mm

Fast-speed injection molding machines have a wide range of applications, meeting the needs of daily household products, as well as injection molding of black and white home appliances and automotive interior and exterior trim. They are the most effective way for injection molding companies to improve quality and reduce costs.

Applications

High-efficiency, low-cost mass production of toys, daily necessities, small and medium-sized plastic products, and thin-wall products.

Technical Parameters

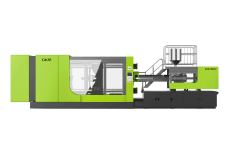

DKM-350VICTOR

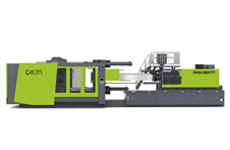

DKM-450VICTOR

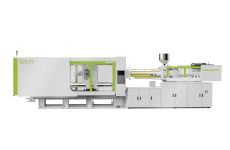

DKM-550VICTOR

DKM-650VICTOR

DKM-850VICTOR

INJECTION UNIT

Screw type(A/B/C)

Screw Diameter

A: 60

B:65

C:70

(mm)

Screw L/D ratio

A: 23

B:21

C:20

(LD)

Injection volume (theoretical)

A: 990

B:1161

C:1347

(CC)

Injection weight (PS)

A: 901

B:1057

C:1226

(G)

Inlection pressure

A: 202

B:174

C:150

(MPa)

Injection speed (max)

200

(mm/s)

Injection rate (PS)

A: 513

B:603

C:699

(g/s)

Screw speed

0-300

(rpm)

Plasticizing rate (GPPS)

A: 70

B:85

C:105

(g/s)

CLAMPING UNIT

Clamping farce

3500

(kn)

Mold movement stroke

640

(mm)

Dist. between tie bars (HxV)

680x680

(mm)

Mold height max.

680

(mm)

Mold height min.

220

(mm)

Ejection stroke

165

(mm)

Ejector force

79

(kN)

Ejector Number

13

(n)

OTHERS

System pressure

21

(MPa)

Pump motor power

62

(kW)

Heater power

22

(kW)

Machine dimension (LxWxH)

6.9x1.74X2.35

(m)

Machine weight

13.5

(t)

Oit tank

400

(L)

Conclusion

In the future plastic molding field, fast-speed injection molding machines are expected to form a well-defined equipment system together with high-speed injection molding machines and ordinary injection molding machines to meet the diverse production needs of different industries and promote the development of the manufacturing industry towards high efficiency, intelligence and greenness.

Get more fast-speed injection molding machine solution