Interpreting a syringe line is important in several business segments, particularly in the health sector of both humans and animals. It is a standard idea that a 1 ml syringe is used to measure the correct amount of liquid medication being given to a patient. Syringe labels are crucial in the veterinary discipline since animals are urged to be administered according to their weight and health status. If one cannot read a syringe line, the chance of under/over-dosing a patient may occur, thus, associated complications.

A disposable syringe line operates on hubs with printings in the exterior part of the hub tip to show progress in volume measurements. These labels and dosage line stickers make it easier for a user to determine the volume of a liquid to be dispensed. The already-filled syringes accompany syringe-filling machines, which have medication syringe labels for veterinary purposes—the 1. A 5 ml syringe is given when the correct dosage is between the scale's 1 ml to 5 ml range. Thus, It will be easy for users to understand how the syringe line works regarding dosage administration.

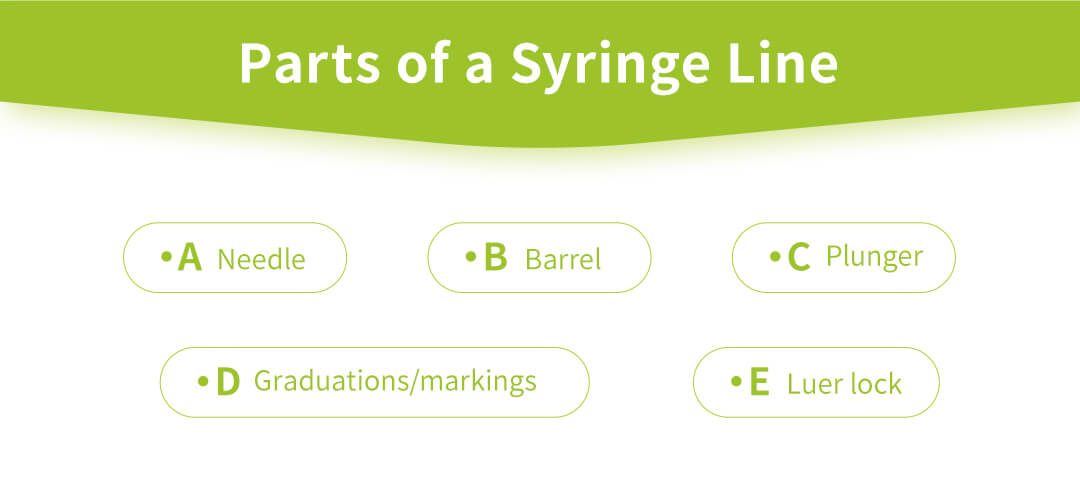

When analyzing different structures of a syringe line, the following components comprise the necessary part of this healthcare device. The first part observed is the needle, mostly created through injection molding to ensure the best quality and durability. Then, there is a syringe barrel containing the medication and graduations/markings around it for measuring the dosage. One of the common types of dispensing mechanisms is using the plunger to advance the medication through the needle into the patient's body. Also, through the Luer lock mechanism, the needle connection to the syringe is enhanced so that no droppings will occur during the injection.

Thus, traditional methods of labelling a syringe with patient information and particulars of the administered medication are employed alongside stickers. These clear label dosage line stickers help the healthcare givers to visually know the correct amount of the medicine that should be given. Thus, whether it is an oral syringe, vial, or flexible syringe, these markings will be easy to read and help minimize misconceptions in medication administration. These 500-piece syringe labels are office supplies crucial for properly using automated syringe systems in medical areas for health and safety.

One widely used technique in manufacturing syringes in the pharma industry is injection moulding. The process entails carving a derived mould for a syringe and then injecting fluid into the cavity of the syringe. An inch dosage marking with a clear label on the syringe is highly recommended for dosage measurements. Among these are the 500-piece syringe labels per roll, which are provided with a dosage line sticker for the syringes to ensure the right portion of the drugs is administered. To manufacture a quality veterinary drug syringe, there is a need to understand the outlook of the syringe line stickers, especially regarding the flow of information.

While discussing pharmaceutical and veterinary syringes, one should pay attention to the graduations and the labels on the syringe. These markings are usually developed using injection moulding technology, making all the syringe line stickers uniform on the products. Whether it is a one, a 100, or any other large number you may be working with, this is good for identifying and assessing risks. This is about the medication syringe sticker or the 5-inch dosage marking clear label, as every small aspect included in the syringe helps ensure that the right fluid dosage is dispensed in the syringe.

Such labels and markings must be read with a lot of attention, and the person who will do it needs lots of concentration. Thus, by understanding how to read the units of measurement (e.g. millilitres) and getting to know the increments on the syringe line, a person can decipher the numbers and lines on the syringe line sticker. It is highly important in pharmaceutical and veterinary drug production, as even the smallest amount of error may lead to dangerous outcomes.

Whether ordering 500 syringe labels in a roll or just putting up a few dosage labels, the label acts as a vital component that helps in proper dosage. By being aware of the dosing marks and clear labelling of syringes, you are assured of the safe and right dosage of administering medication or fluids. One must pay attention to these markings to enhance the success of the implemented treatment plans.

In general, the application of a syringe line also has some specific rules that should be complied with to achieve better results. First of all, the position of holding the syringe line determines a lot in this matter. When designing the syringe labels and the line stickers, the right syringe moulding of the plastic pieces should be adjusted to give a firm and steady position when giving the medication to the patients.

Bearing in mind the control measures that have been put in place, filling the syringe line with medication should be delicate. syringe filling machines play an important role here as they can help fill the syringes properly. It entails decanting to remove bubbles, which may affect the calculation of the dosage. The dosage marking clear label on the syringe line sticker is relevant in measuring the right quantity of medicine that needs to be given to the patient.

The administration of medication using a vet drug syringe label needs to be accurate to avoid complications. Therefore, correct use of RTU aseptic nest filling systems can assist in giving accurate doses and avoiding mistakes. Customer specifications and information on the web may also help in the right usage of the syringe line, especially for nursing school candidates preparing for the NCLEX.

Some of the most important things one should avoid when working with an injection machine in pharma production are the mistakes that may lead to the loss of dosage accuracy. The following are the common drawbacks:

One of the most probable errors is misunderstanding of the marks on the syringe line, which, in turn, leads to the injecting of the wrong dose of the medicine to the patient. In this regard, special attention should be paid to reading label syringe line stickers on the syringes. The other mistake to avoid is not removing all the air that might be present in the syringe before administration; this also plays a role in the dosage delivery. Further, if the wrong syringe line is employed, it contributes to dosing mistakes. Another key issue is that in some organizations, patients are jeopardized by exposure to wrong information. The right type of syringe line stickers should be used, particularly the type with the number 1. 5 dose mark line, so that people can accurately measure it. Syringes vary in size. Thus, a proper match of a syringe barrel and nozzle should correspond to the type of medication. Do not forget to double-check the marking clear label dosage line and the sticker on the syringe medication to ensure that the right dosage is delivered.

It is vitally important to use an accurate method when reading a syringe line. Just as important is the need to institute appropriate labels on the syringes or syringe line stickers, as this assists in identifying the right syringe. Dosage marking should be very clear, and the labels should be intelligible regarding the amount of medication administered in the syringe. It was noted that stickers for syringes are extremely important in administering medications, particularly when the medications are considered high-risk.

To read a syringe line, it is always important to be able to read the following measurements: 1000 × 0. 01 ml. For correct dosing, the syringe's piston and stopper must also be in the right position. Due to the possibility of mistakes resulting from poor filling and stoppering, proper techniques should always be used. By employing products that are certified and fully automated processes, which DKM, for instance, has to offer, the pre-filled syringing can be realized optimally and safely.