Sino Holdings Group at Chinaplas 2021

DKM Intelligent Injection Molding Solutions - make plastic molding more valuable

Sino Holdings Group will be presenting the automatic plastic production lines of plastic food containers, medical PET tubes and 20L IML paint pails at Chinaplas in Shenzhen, China, from 13th to 16th April, 2021. Visit us on Booth No.: 9J21 & 9J35 to discover our intelligent plastic injection molding solutions for quality and efficient production.

How to make more value for users is the mission that we - one of the industry leaders - have been focusing on for years, so we show you the latest injection molding system with our innovative technologies by such three practical examples.

DKM Plastic Food Container Injection Molding Solution

It will be on display that DKM-300HH produces 4 PCS plastic containers for food packaging industry using a 4-cavity container injection mould from Sino Mould. We have been continuously researching and developing on plastic thin-wall containers injection molding solution to make effort for Eco friendly.

Here, the specification for the line is showed for your reference:

| Project | 450ml Food Containers | ||

|---|---|---|---|

| Mould | Food Containers Injection Mould | mould cavity number: 4 core and cavity steel: 2344 + Beryllium Copper runner: Anole 4 tips valve hot runner mould size: 500*500*582 mm |

Provides the solution to meet your demands. |

| Machine | DKM-300HH | Powerful high speed injection molding machine – maximize output – precision molding, fast response, shorter cycle times. | |

| Automatic system | Robot + Conveyor | Pick up and conveying the containers for further processing. | |

| Auxiliary equipment | Auto loader Air chiller Air compressor |

Help to deliver energy-efficient production with consistently high quality product. | |

DKM 32-cavity Medical PET Tube Injection Molding Solution

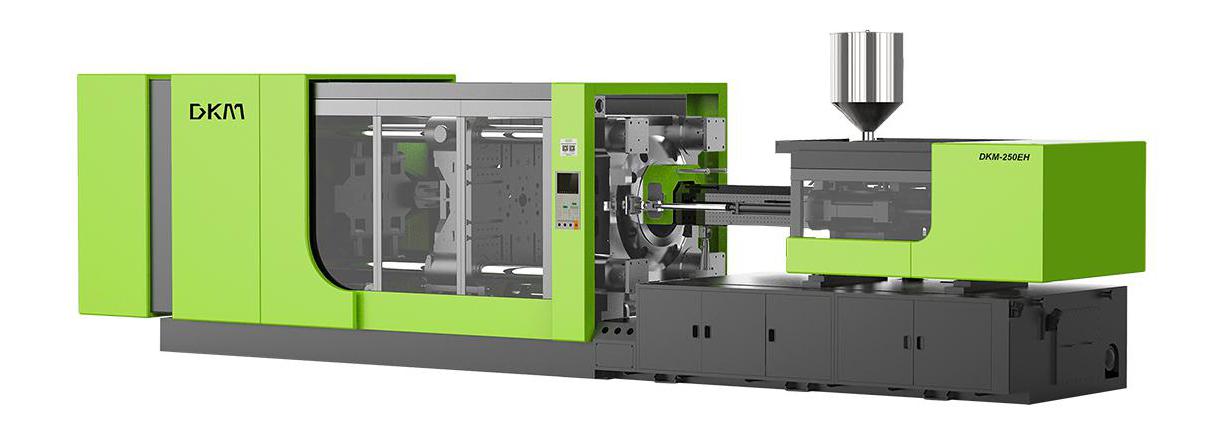

DKM-250EH produces 32 PCS PET tubes for medical industry in a cycle time of 10-12 seconds using a 32-cavity mould from Sino Mould. The whole line is at stable running with the shortest cycle time thanks to the high performance of machine and moulds.

Here, the specification for the line showed for your reference:

| Project | Medical PET Tubes | ||

|---|---|---|---|

| Mould | PET Tube Mould | mould cavity number: 32 core steel: S136 (ASSAB) cavity steel: DC53 runner: Anole 32 tips valve gate mould size: 660*500*478 mm |

Production capacity: About 3,594,240 PCS/Month (as the working time: 12hours*26days) |

| Machine | DKM-250EH | High speed injection molding machine with fully electric injection unit – high injection speed, high precision and shorter cycle times. | |

| Automatic system | Conveyor | Delivery the tubes from down to top for next step. | |

| Auxiliary equipment | 3-in-1 dehumidifying dryer | Help to deliver consistently high product quality. | |

DKM 20L IML Plastic Paint Pail Injection Molding Solution

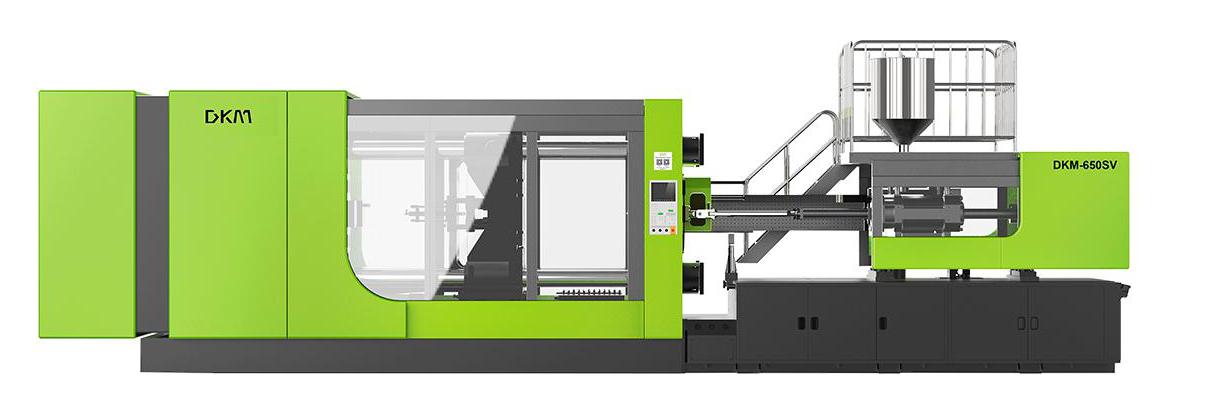

A unique DKM-650SV injection molding machine fully automatically produces one 20L plastic paint pail with In Mold Labeling (IML) made from HDPE in a cycle time of 15 seconds. The pail surface printing takes place within the injection molding cycle by means of IML robotic system, which increases the production quality and efficiency.

Here, the specification for the line showed for your reference:

| Project | 20L IML Plastic Paint Pails | ||

|---|---|---|---|

| Mould | 20L Paint Pail Mould | mould cavity number: 1 core and cavity steel: P20 +Beryllium Copper runner: Anole 1 tip hot runner mould size: 700*700*902mm |

Production capacity: 74880 PCS/Month (as the working time: 12hours*26days) |

| Machine | DKM-650SV | Designed with suitable clamping unit and injection unit for buckets, and with synchronous plastic charging – achieving highly efficient production of quality parts. | |

| Automatic system | IML system | In Mold Labeling equipment suitable for efficient production with higher safety protection. | |

| Auxiliary equipment | Auto loader | Help to deliver consistently high product quality & maximum machine availability. | |

Watch the Video of Related Injection Molding Solutions in Advance

A unique DKM-650SV injection molding machine fully automatically produces one 20L plastic paint pail with In Mold Labeling (IML) made from HDPE in a cycle time of 15 seconds. The pail surface printing takes place within the injection molding cycle by means of IML robotic system, which increases the production quality and efficiency.

What we can help you

Select Suitable Machine & Equipment

Select Mould Cavities Nr. And Other Parameter

Automation Manufacturing System Suggestions

Machine Assembling Foundation Layout (including send person assistance )

Operator Train Before Machine and Moulds shipment

Hunting Chinese Engineer or Management Officers

Machine & Mould Installation & Running

On Site & Online Training

TOP Automation Manufacturing Software

We have more than 20 years of know-how in plastics injection molding solutions. In addition, we are advancing the intelligent systems and the response of our services globally. Our customers (most of them are plastics manufacturing companies) benefit from DKM turnkey solutions that enable them to boost quicker production efficiency, higher added value, and more stable running reliability - from the DKM quality injection molding machine with the best injection mould to the cost-efficient & complete guidance and timely services.

Maximum output with minimum energy consumption solution is here for you.

Welcome to book an appointment with one of our sales team in the following contact from. And if you’d like to get the latest news, welcome to follow us now on our LinkedIn or Facebook pages or Twitter or YouTube.