For manufacturers looking to solve persistent challenges in injection molding, Dakumar's High-Gloss No-Marking Injection Molding Technology offers a solution that addresses the critical needs of the industry. This technology, also known as Rapid Heat and Cool (RHCM) Injection Molding Technology, is designed to solve issues like surface defects, long cycle times, and high production costs. By improving efficiency and product quality, it helps manufacturers meet industry demands.

Key Issues Addressed:

· Surface Defects: Prevent common problems such as weld lines, flow marks, and sink marks.

· Efficiency: Shorten cycle times by over 60%, leading to increased productivity and cost reduction.

· Environmental Impact: Reduce the need for secondary coating processes, lowering waste and conserving resources.

For industries where appearance plays a vital role, such as consumer electronics, automotive interiors, and high-end home appliances, the quality of a product's surface is essential. With our High-Gloss Injection Molding Technology, manufacturers can achieve impressive surface finishes while ensuring durability and reducing costs.

· Flawless Surface Quality: Our technology prevents common surface defects like welding lines and sink marks, ensuring a smooth, high-quality finish. By keeping the mold at the best temperature during injection, the process delivers parts that meet the highest standards in the industry.

· Striking Polished Surfaces: Products in sectors like automotive interiors and consumer electronics receive help from a polished, high-gloss surface. This technology ensures that the final product has a striking, mirror-like appearance that enhances its visual appeal without additional finishing processes.

· Improved Durability: Beyond aesthetics, the technology also increases surface hardness and part strength. This ensures that products can withstand everyday use while supporting their high-quality appearance.

Aspect | Traditional Injection Molding | High-Gloss Injection Molding |

Surface Quality | Prone to weld lines, flow marks, and sink marks | Flawless, polished, mirror-like surfaces |

Production Cycle Time | Longer due to standard cooling times | 60% reduction in cycle time |

Environmental Impact | Requires secondary processes like coating | No secondary processes needed, reducing environmental footprint |

Product Durability | Standard durability | Improved surface hardness and strength |

Dakumar's High-Gloss Injection Molding Technology is distinguished by its unique approach to heating and cooling, which allows manufacturers to produce high-quality parts quickly and efficiently. This process stands out from traditional injection molding methods in several key areas:

1. Heating the Mold: Unlike conventional methods, where the mold stays at a consistent temperature, this process begins by heating the mold. To rapidly increase the mold temperature to 150℃-180℃. This helps improve material flow and prevent surface imperfections, ensuring a consistent, high-quality result.

2. Immediate Injection: After the mold reaches the desired temperature, injection begins right away. The key is supporting high mold temperatures during the injection phase to ensure smooth material distribution and prevent defects.

3. Rapid Cooling: When starting the pressure holding, immediately cool the mold's molding area down to 1℃-15℃. This reduces cycle times by over 60%, allowing manufacturers to boost production efficiency. Additionally, the rapid cooling process improves surface hardness, resulting in a denser molecular structure that enhances both appearance and durability.

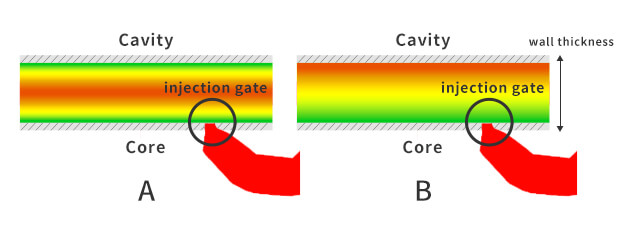

Picture A is the traditional process, where you can see the melt plastic flowing in the middle layer, and the area close to the surface of the molding area has already cooled down. Therefore, when the melted resin is combined in different directions, the weld line will inevitably occur.

Picture B is using high gloss injection molding technology. The upper surface is still at high temperature, the melt plastic continues to flow against the mold surface, while the lower layer of the product cools down. In this situation, the surface defect will disappear. Please refer to the following image.

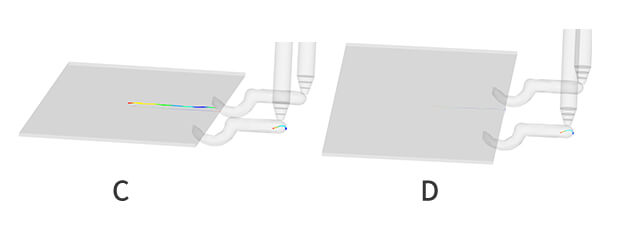

There is a weld line on the surface and reverse side of the product in Picture C. In Picture D, the weld line which is on the product surface just disappears. This is the charm of high-gloss injection moulding, providing perfect product surface.

Producing high-gloss, no-marking plastic parts requires precise configurations across multiple components of the injection molding process. These include the injection molding machine, mold design, and the use of specialized plastics. Ensuring that each of these elements is correctly configured is crucial to achieving the desired results.

1. Injection Molding Machine Configuration: Improving the machine setup is essential for producing high-quality parts:

o Shot Volume Adjustment: Depending on the product, the shot volume must be adjusted to prevent material degradation and achieve the best possible surface finish. For example, producing flat-panel TV frames requires a shot size that falls between 30% and 80% of the machine's theoretical shot capacity.

o Specialized Screw Design: The screw in the injection molding machine must be designed specifically for high-gloss plastics. This ensures proper plasticization while minimizing shear forces, preventing material degradation.

2. Mold Configuration: A well-designed mold is essential for producing flawless surfaces and reducing cycle times:

o Polished Internal Surface: The mold's internal surface must be polished to a mirror-like finish. Any imperfections in the mold will transfer to the final product, compromising both appearance and performance.

o Efficient Cooling/Heating Lines: The mold's internal cooling and heating lines need to be designed to allow rapid temperature changes. This ensures consistent surface quality and shorter cycle times.

3. Specialty Plastics: Material selection is critical to the quality of the final product. High-gloss applications require the use of plastics like ABS, PC+ABS, or PMMA+ABS, each offering varying levels of hardness and flowability. Selecting the right plastic is essential to balancing surface quality with mechanical strength.

Component | Requirement |

Adjusted shot volume (30%-80% of theoretical capacity), specialized screw design for high-gloss plastics. | |

Mold Configuration | Polished internal surface, efficient heating/cooling line design, thermally conductive mold steel. |

Specialty Plastics | Use ABS, PC+ABS, or PMMA+ABS based on hardness and flowability requirements. |

High-Gloss Injection Molding Technology is ideal for industries that demand top-tier product appearance and quality. This technology has been widely adopted in industries such as consumer electronics, automotive interiors, and high-end home appliances, where both performance and aesthetics are critical.

· Home Appliances: High-end home appliances like refrigerators and air conditioners benefit greatly from our technology. The flawless surface quality ensures that these products meet high customer expectations, while the improved efficiency and durability keep production costs low.

· Automotive: Automotive interiors are increasingly focused on appearance, and this technology allows manufacturers to produce components with a premium look and feel. High-gloss finishes elevate the visual appeal of automotive interiors, while enhanced durability ensures that parts can withstand daily wear and tear.

· 3C Digital Products: The sleek, polished appearance provided by this technology is particularly beneficial for manufacturers of consumer electronics such as laptops, monitors, and smartphones. The high-gloss surface is key to attracting consumers who prioritize design.

Industry | Applications |

Home Appliances | Televisions, air conditioners, refrigerators, etc. |

Automotive | Interior components, headlamp housings, etc. |

3C Digital Products | Computer monitors, smartphones, electronic devices, etc. |

High-End Consumer Goods | Luxury packaging, premium product casings, etc. |

Medical Devices | Diagnostic instruments, high-quality casings for medical equipment, etc. |

Dakumar's High-Gloss Injection Molding Technology stands at the forefront of innovation in the injection molding industry. By using advanced heating and cooling techniques, this technology improves surface quality, reduces production times, and removes the need for environmentally harmful secondary processes. It gives industries the ability to produce high-quality, visually appealing products while minimizing costs and environmental impact.

With our ongoing commitment to creating better solutions, Dakumar continues to support manufacturers worldwide as they adapt to changing market demands. Whether your goal is to improve the appearance of your products, reduce production costs, or increase efficiency, Dakumar's High-Gloss Injection Molding Technology provides the tools you need.