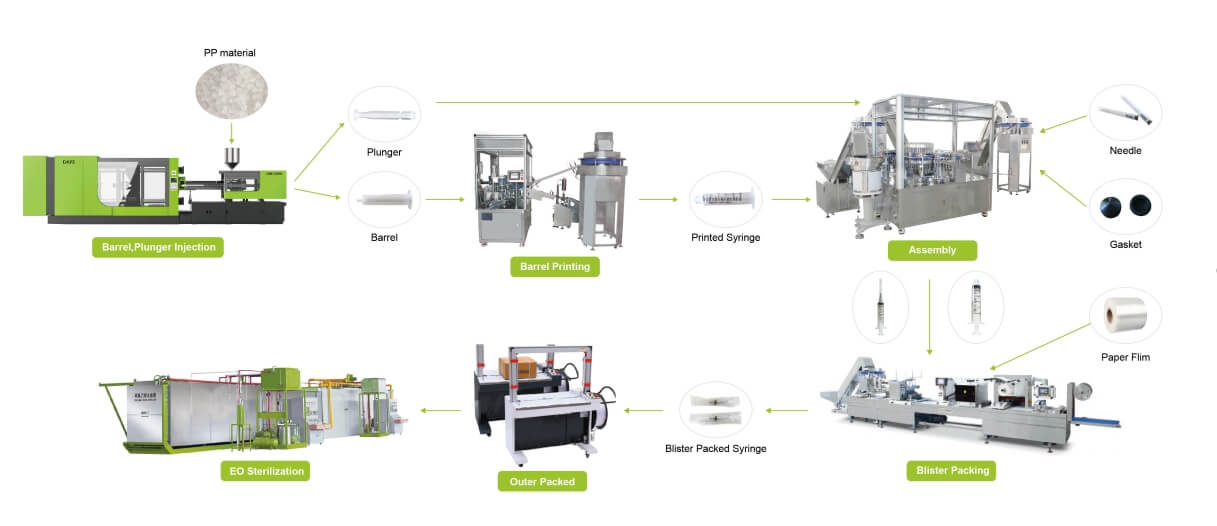

The vacuum blood collection tube machine consists of several things like, loading the tubes, filling the tubes, capping the tubes, and loading the trays. The assembly machine also plays an important role in making sure that the blood collection tube is filled with the correct amount of anticoagulant and closed with a stopper to check vacuum pressure. This operation must, therefore, be performed carefully since even the slightest mistake can influence the results of medical tests.

Furthermore, the vacuum blood collection tube-making equipment produces blood collection tubes with a higher degree of automation. Utilizing this kind of equipment ensures the creation of superior blood collection test tubes while also freeing up the operator's physical strength. The fabrication of vacuum blood collection tubes requires meticulous attention to detail because any impurity could compromise the accuracy of the blood tests that will be performed.

In past years, the process of blood collection without a vaccum was quite difficult. It required a great deal of proper handling. But with time, manufacturing machines were introduced that were able to create excellent blood collection tubes.

The production line for blood collection tubes has also developed, and now it incorporates tube loading, anticoagulant blood collection test vacuum, and reverse tubes for various uses. They are accurate in the processing of blood collection tubes and have brought a change in the sampling system in hospital labs. Moreover, new vacutainer anticoagulant blood collection test machines have also eased the process and even eliminated some levels of mistakes.

When it comes to the blood collection tube machine, the critical parameter that needs to be met is the precision of the processing. Thus, the blood collection tube assembly section is made efficient and accurate with the use of a tube injection moulding machine and a plastic injection moulding machine.

There is also the advantage that the operation of this new generation machine is done automatically. The filling machine and disposable syringe-making machine complement each other and efficiently perform vacuum and non-vacuum blood collection, eradicating the influence of the human operator.

Time-saving in sample collection is one of the significant advantages of the blood collection test tube manufacturing machine. These features, such as the automatic blood and chemical dosing in the machine, enable the samples to be collected and processed within a short time and accurately as opposed to the initial time-consuming process that the hospital laboratory Vacutainer anticoagulant blood and lab Vacutainer anticoagulant blood collection involved.

In conclusion, the features of the used vacuum blood collection tube Machine show that it can be critical equipment in enhancing the functionality and quality of any health facility engaged in sample collection.

Accumulating blood using a vacuum blood collection tube machine has many advantages for clinics and different healthcare structures. Thus, by employing these instruments, healthcare practitioners can aim to achieve better accuracy in the outcomes as the vacuum system helps to deliver constant and proficient samples. As opposed to the conventional non-vacuum BD blood collection tubes, the vacuum tubes assist in mitigating the chances of contamination and inaccuracy during the blood collecting procedure. This is because they give precise and trustworthy results to the patients in the end as opposed to other testing techniques. Further, one gets to use a blood collection tube machine to avoid the time-consuming exercise of labelling the tubes and handling the samples, which is a commendable effort for healthcare providers.

Moreover, testimonials from healthcare professionals stress the advantages of using blood collection tube machines in their practice. These testimonials bring to light the main benefits of having an integrated blood collection tube-making machine, ranging from the aspect of having lower maintenance cost as compared to frequent individual purchases of these tubes to visions of productivity enhancement in future due to the manufacturing of these bottles. Further, aseptic disposable blood serum tubes and the blood serum tube rack are also easy to use, which augment the medical facilities’ efficiency.

When comparing vacuum blood collection tube machines, leading manufacturers in the market, as well as aspects of difference and advantages of the various machines, are points to be considered. These machines are commonly used in the medical field to help with the collection of blood samples and are precise.

One of the critical areas that is visible and easily identifiable for the operation of these machines is the HMI control, which is an interface for operating the machines. Also, issues that pertain to measurement, like the overall dimension, should be considered, as well as features that relate to what the blood collection tube machinery is a part of, in this case, the whole line. It is also necessary that the vacuum blood tube production machine is evaluated on the production abilities of the blood collection tubes.

Thus, every machine has its characteristics and nuances that should be considered before purchasing it. The key players in the market have made it possible for clients to select a number of options with regard to machine blood collection tube technology, depending on their client's requirements. Some features like non-vacuum blood collection and integrated blood serum tubes must be analyzed with attention to select the right equipment for further work.

This particular line of vacuum blood collection technology is predicted to have a great future and develop in the years to come. A specific area of advancement is in precision processing, where blood collection tube machines are being developed with improved precision and productivity. This will increase efficiency and effectiveness in taking blood samples for various tests, therefore making them accurate.

When such machines are integrated into large systems, various healthcare providers are able to integrate their activities into single flows, which makes their work more effective. This integration also has the opportunity to improve the existing quality of the offered patient care services by ensuring the timely and accurate way of blood sample collection.

Automated vacuum blood collection tube machines have the following advantages for healthcare facilities:

These machines help standardize the method of blood collection and, hence, the rate of flow and precision of other procedures. Proper sample collection is made possible by a newly introduced integrated blood collection tube system. Also, the overall dimensions of the machine are comparatively smaller, which makes it convenient to fit in medical facilities. The vacuum blood collection tube machine is applied for several purposes, including manufacturing plastic blood collection tubes.

There is a call for the implementation of this novel technology in healthcare facilities. Thus, the integration of the blood collection tube machine would be the catalyst for better patient care delivery and increase the effectiveness and efficiency of operating facilities. A vacuum blood tube production machine is beneficial in solving these problems and provides a safe and essential environment in which to collect blood samples, which helps healthcare units and patients better.