In the world of plastics, one of the most important tasks is to find out the precise and perfect size of the projected area. This is not only important for the newcomers but one of the skills that no matter how much experience you have you must invest time to get a perfect projected area for the injection molding. As it helps you to know how to get a design for mold, how much force to use, what material and what temperature one should use. So it is very important to know How to calculate projected area for injection molding. Thus, in this guide, we are going to explore the idea of the projected area in plastic molding and why it is important to get a perfect understanding of this area.

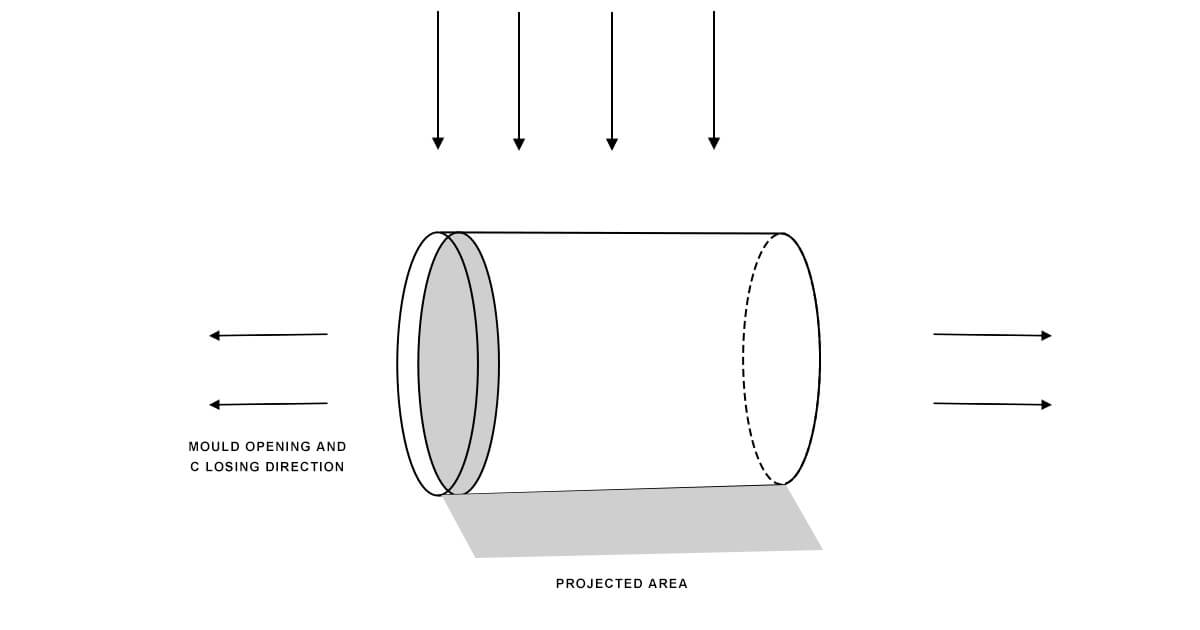

Projected area is important in the world of plastic and molding activities. To get an easy understanding, let us tell you that projected area involves a picture of a three-dimensional object that is viewed in two different dimensions. Or in simple work, we can say it is all about viewing three-dimensional objects on one flat surface.

In the context of plastic injection molding, this projected area becomes an important parameter. The projected area helps us to roughly estimate the force that is used to apply on the mold in the molding procedure. This force is actually called the clamping force and this force is commonly referred to as clamping force, and its accurate calculation is vital for ensuring the proper formation of the plastic part.

Let’s imagine we need to shape a product and for this, we use injection molding process. The mold needs to be held securely closed during this injection to ensure that the plastic takes the desired shape. Thus, there the projected area will help us to determine the amount of force that is required to keep the mold closed and withstand the pressure of the injected plastic. But Here the question that occurs is How to calculate the projected area for injection molding?

Why should we learn how to calculate the projected area for injection molding? Let’s discuss the significance and know the reason.

The projected area impacts the clamping force directly and this force is used to keep the mold securely closed during the injection process. Clamping force is the pressure that ensures the mold stays shut while molten plastic is injected. It is very important that one properly calculate the projected area because this is the only way we can estimate the clamping force. This is important for achieving high-quality and defect-free molded parts. If the clamping force is not enough, it may result in incomplete mold completion, leading to defects and low product quality.

To get the best quality molded parts is one of the basic rules and goals in the procedure of injection molding. And in this procedure, the projected area is the key factor by helping manufacturers optimize the clamping force. When the clamping force is accurately calculated with the help of the projected area, it tells us that the mold remains closed during the whole injection process. Thus, this provides the production of the perfect and desired product.

As we have discussed above the projected area is important to get to know about the clamping force but here is one important thing that also helps us to select the right injection molding machine for our desired job as well. Different projects may require varying levels of clamping force, and the projected area guides manufacturers in choosing a machine that aligns with the production requirements. Thus, inaccurate projections can lead us to unrequired molding machines, wrong clamping force and much more.

Accurate knowledge of the projected area facilitates the optimization of the entire injection molding process. From selecting the appropriate machine to setting the right clamping force, manufacturers can streamline their operations for maximum efficiency. This calculation not only increases the quality of molded products but also improves the use of products and results.

Except for clamping force and selection of machine the projected area also helps the person to enhance the product life. It protects the products from early decayMolds are expensive and intricate components of the injection molding process. Inaccurate projections can lead to excessive force or pressure on the mold, potentially causing wear, damage, or even failure. When one estimates the projected area the manufacturers protect their molds, increase life span, and reduce maintenance cost.

Let’s discuss how to calculate projected area for injection molding:

Before discussing the calculation process let’s understand the basics of projected area. As we have discussed above. The projected area is perpendicular to the mold opening and we image the product in a two-dimensional picture just like the perspective of the mold.

The first step is finding the jewllery of plastic. In it, we find the outer boundaries, cross-sectional area and other features.

If the image is complex it is best to break the complex shape into multiple simpler ones. As the shapes when single are easy to calculate and understand in the projected area.

We can calculate the projected area by multiplying the length and width. However, many other formulas can also be used to calculate. Like circular features, involve the use of π (pi) in their formulas.

There are some designs that contain cuts and complicate the projected area. These features should be carefully included in the overall calculations.

Start by examining the plastic parts by identifying the outer boundaries and cross-sectional features.

If the shape of the product is complex, we will break it down into simpler shapes by this the geometric shape can be simplified.

After this now use the correct mathematical formulas for each geometric shape to calculate their individual projected areas.

Now add all the areas of shapes into one to obtain the final number.

If there are undercuts then add them in the final area to get the accurate number.

Let's say we have a rectangular part with dimensions:

· Length (L) = 100 mm

· Width (W) = 50 mm

· Thickness (T) = 10 mm

To calculate the projected area, you can use the formula:

Projected Area = Length (L) × Width (W)

In this case:

Projected Area = 100 mm × 50 mm = 5000 mm²

So, the projected area of the rectangular part is 5000 square millimeters. This calculation gives you an estimate of the surface area that the mold will need to accommodate during the injection molding process.

In conclusion, Learning how to calculate projected area for injection molding is a skill that can significantly impact the efficiency and success of plastic manufacturing processes. From understanding the basics of projection to breaking down complex shapes and utilizing mathematical formulas, the process requires attention to detail and a thorough understanding of the part geometry.

As demonstrated through the real-world application with DKM injection molding machines, accurate projected area calculations are essential for optimizing clamping force, selecting the right machinery, and ultimately ensuring the production of high-quality plastic parts. As the injection molding industry continues to evolve, a firm grasp of projected area calculation remains a valuable asset for manufacturers and engineers alike.