An injection machine can be described as a tool applied to produce plastics. These machines involve a mold in which molten material is poured and takes its shape after cooling. Injection machines are the main equipment used in manufacturing products since they enhance high precision and output, and cycle time is minimized. All-electric injection molding machines help attain higher cycle rates, less space, and energy control in modern production. They also improve injection performance and force compared to hydraulic injection molding machines. Furthermore, injection molding machines comprise multi-plate injection molding, and all-electric injection molding, which helps to have more versatility depending on their usage.

It remains one of the most distinguished processes through which it forms the required plastic part by injecting molten material into a mold. The injection machines revolve around melting small plastic pellets and then injecting the molten material into the mold, cooling and solidifying it into the required shape. This is the work of the machine's injection unit; it ensures high injection pressure to fill the mold cavity. Some of these Large injection molding machines are accompanied by an electric injection molding machine with a servo-hydraulic drive that enhances energy intake. These machines provide a better finishing of the surface and sequence in the production process.

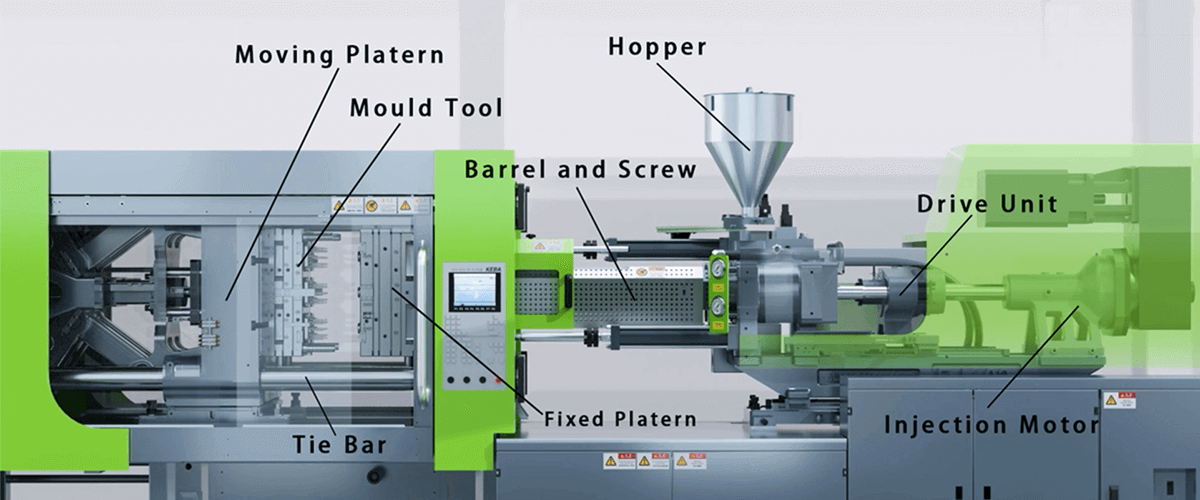

The injection machine contains:

· A clamping unit with platen and tie bars.

· Many cavity systems.

· A runner system.

· A tool for insert molding.

This is the chronological process of how injection machines work.

Turnkey operations of the injection machines start from the hopper, where the plastic pellets are fed to the machine. The key products in the Duo tech series, with the servo drive system and toggle clamping unit, are of high quality for over-molding and could produce mold complex parts.

Today, there is a wide variety of injection machines and production types that can meet the interests of various molding companies.

Among the most commonly selected hydraulic injection machines are the high-tonnage

machines best suited for using large molds.

Electric injection machines are also gaining a high proportion of use because they are energy-saving friendly and have fast duo speeds.

There are injection machines with hydraulic and electrical functions, and for molders needing both functions, hybrid injection machines will be the best since the force is distributed evenly. The time taken on the dry cycle can also be shorter.

Thus, due to either the increasing difficulty of sourcing new locations in which the company can build new plants and increase its production or the growing availability of new vertical injection machines, molders can select either the horizontal or the vertical injection machines according to the available space in the plant. Similarly, advancements in electric machines have made it possible to have benchtop injection machines suitable for specific uses or even cleanroom production lines. Also, in multi-component injection machines with a hot runner system, the molders were heave tool wear and improved overall efficiency.

The following are some of the pros associated with the application of injection machines:

Another factor is the efficiency of the costs since these machines help manufacture numerous products successfully, therefore minimizing the time required for employees to spend on production.

The compactness of these machines also determines space conservation when placed in the manufacturing facility, especially for companies that wish to conserve floor space.

Furthermore, the employment of linear guides in injection machines helps ensure accuracy when molding various products, hence providing quality goods.

Moreover, the versatility that accompanies the use of different materials in the injection

machines helps provide many products.

Due to the versatile industries that use injection machines, they remain crucial equipment in the manufacturing industry. In the automotive line, injection machines produce large mold-size parts like the dashboard, bumpers, and panels. These machines are also used widely in packaging enterprises to produce numerous products such as bottles, caps, and containers. In the medical industry, injection machines are essential in manufacturing many medical instruments, equipment, and facilities and in producing and supplying essential devices and instruments. Furthermore, the consumer goods industry employs injection machines, which make commodities such as toys, utensils, and household items.

Ergonomics is thus a critical factor in the design and management of injection machines for the welfare of workers and productivity improvement. With technological advancement, the method is antediluvian while organizations are shifting and expanding their capital on the modern advanced injection machines. Thus, through internal production, the firms reduce the time taken for production stoppage and accessibility of a new strategic position in the market. Therefore, injection machines are effective and multifunctional tools widely used in different industries and help provide high-quality results.

Maintenance of injection machines is very important if they are to run efficiently and for a longer duration. Daily maintenance consist of ensuring that all harsh particles do not

accumulate on the components and applying a spare lubricant to reduce wear and tearing that results from friction. Also, temperature and pressure settings, for instance, should be carefully observed to avoid cases of overheating and related complications.

Problems that might occur with the injection machines include nozzle blockage, variation in the extent of filling the cavity, and flashes. To resolve these problems, you can wipe the nozzle with a wire or remove any disturbing obstacle. Odd filling or flashing can also be solved by changing the filler position or the pressure settings. In this case, mold inspection may be possible without encountering any defects.

Like other machines, the various injection machines should be checked and serviced often to prevent small problems from becoming larger. Daily or weekly inspections of the machine parts enable the operators to see that some of the components are worn out or leaking, and this will lead to expensive repairs or lengthy downtimes. It also assists in avoiding large-scale failures and guarantees that the machine is running in its best condition.

Manufacturers can have a more direct and effective production plan in today's world. Hence, their efficiency and effectiveness are

boosted, and time wastage is greatly minimized. Secondly, injection molding has also been boosted through robots, especially for complicated moldings. Robots can be precise in performing some operations, increasing the quality of the parts produced and the production rates.

Another concern of injection molding practices is that sustainability in manufacturing is

likewise slowly gaining the attention it deserves. Today, there are new convenient

technologies for recycling materials to produce new goods; energy-saving technologies are also being developed actively. Since goods must be made to consumer's specifications, manufacturers can reduce waste and thereby decrease their impact on the environment while continuing to create items of a high caliber. Unfortunately, such business advancements to make production sustainable also benefit the environment by saving on materials costs and energy use in the long run.

In summary, the present advances in technological aspects, particularly injection machines, are really shifting the manufacturing industry to a different level. With

zero integration, robot-assisted injection molding, and sustainable manufacturing methods, companies are now in a position to produce much improved and higher volumes with lesser negative impacts on the environment.

Based on the points highlighted in this article, injection machine technology is undoubtedly critically important in manufacturing activity. We distinguished the kinds of innovations on injection machines, including enhanced accuracy and speed that have greatly impacted the production segment. In addition, we also explored the future emerging technologies of injection machines, which include the use of artificial intelligence and machine learning that will improve the efficiency and effectiveness of the machines.