Weld lines, also known as knit lines or meld lines, are a frequent challenge in the injection molding process. These lines are more than just a cosmetic issue; they can significantly weaken the integrity of the molded part, leading to potential failures under stress. For manufacturers, avoiding weld lines is essential to ensure product durability and aesthetic quality.

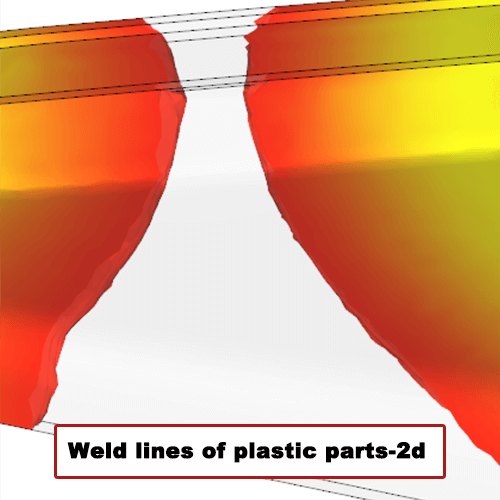

Weld lines occur when two flow fronts of molten plastic meet within the mold but fail to fuse seamlessly. This can result in a visible line on the surface of the part, which is often a weak point in the structure. Understanding the root causes of weld lines is the first step toward preventing them.

Weld lines form when the converging angle of the flow fronts is less than 135°, while meld lines occur at angles greater than 135°. Both types can impact the strength and appearance of the molded part, though weld lines are more severe.

Several factors can contribute to the formation of weld lines, including:

● Injection Pressure: Low pressure may result in an inadequate fusion of the plastic flows, leading to visible weld lines.

● Melt Temperature: If the plastic cools too quickly, it might solidify before fully merging, resulting in weak weld lines.

● Mold Design: Inconsistent wall thickness or poorly placed gates can disrupt the flow, causing weld lines.

● Injection Speed: Slow injection speeds can cause uneven cooling, which increases the likelihood of weld lines.

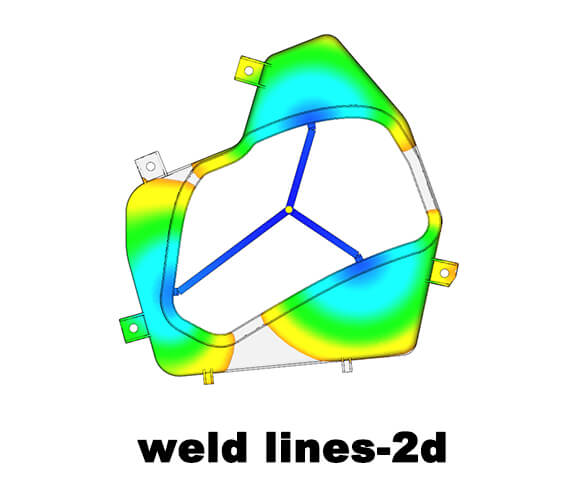

Proper mold design is critical to preventing weld lines. Designers must ensure consistent wall thickness and strategically place gates to promote uniform flow. Simulation software can be invaluable in optimizing mold design to reduce the risk of weld lines.

The choice of material plays a pivotal role in the likelihood of weld line formation. Materials with high viscosity or those containing impurities are more prone to weld lines. Selecting the right polymer and ensuring material purity can significantly reduce the occurrence of these defects.

Additives such as colorants or impact modifiers can either help or hinder the formation of weld lines. It is crucial to choose additives that are compatible with the base material and do not adversely affect the flow or fusion of the polymer.

The settings of the injection molding machine are critical in controlling weld lines. Parameters such as injection speed, temperature, and pressure must be carefully calibrated to ensure the optimal flow of molten plastic.

Parameter | Effect on Weld Lines | Recommended Adjustment |

Slow speeds can cause uneven cooling and more weld lines | Increase speed to ensure even flow and cooling | |

Melt Temperature | Low temperatures lead to premature solidification | Maintain a consistent and optimal melt temperature |

Injection Pressure | Insufficient pressure can prevent proper fusion of flows | Adjust pressure to ensure seamless merging of flow fronts |

Gate Location and Design | Poor placement can cause flow disruptions | Optimize gate placement for balanced flow |

Material Purity | Impurities can obstruct flow, leading to weld lines | Use high-purity materials to ensure smooth flow |

Efficient cooling is essential to avoid weld lines. The cooling process should be uniform to prevent any part of the material from solidifying prematurely, which can lead to the formation of weld lines.

Using advanced cooling techniques, such as cyclic cooling or conformal cooling channels, can help maintain consistent temperatures throughout the mold, reducing the risk of weld lines.

Beyond basic adjustments, advanced techniques such as co-injection molding and hot runner systems can further reduce the incidence of weld lines.

Co-injection molding allows for the injection of different materials into a single mold, improving the flow characteristics and reducing the likelihood of weld lines.

Simulation software is a powerful tool in predicting and preventing weld lines. By modeling the injection process, engineers can identify potential issues and make adjustments before production begins.

Simulation Tool | Purpose | Outcome |

CAE Software | Predicts flow issues and weld line formation | Allows for early adjustments to prevent weld lines |

Prototyping | Tests mold design in real-world conditions | Provides data for further mold and process optimization |

Regular maintenance of molds is essential to prevent weld lines. Residue buildup or wear can interfere with the flow of plastic, leading to defects.

Regular inspections and cleaning of molds ensure that the flow paths remain unobstructed, reducing the likelihood of weld lines and other defects.

Continuous training for operators and ongoing optimization of the injection molding process are crucial for maintaining high-quality production and minimizing weld lines.

Implementing a system of continuous improvement, where injection parameters are regularly reviewed and adjusted, can significantly reduce the occurrence of weld lines.

Weld lines are a common but preventable issue in injection molding. By focusing on material selection, mold design, and process optimization, manufacturers can produce high-quality parts with minimal defects. Regular maintenance, operator training, and the use of advanced technologies further enhance the ability to avoid weld lines and ensure product integrity.