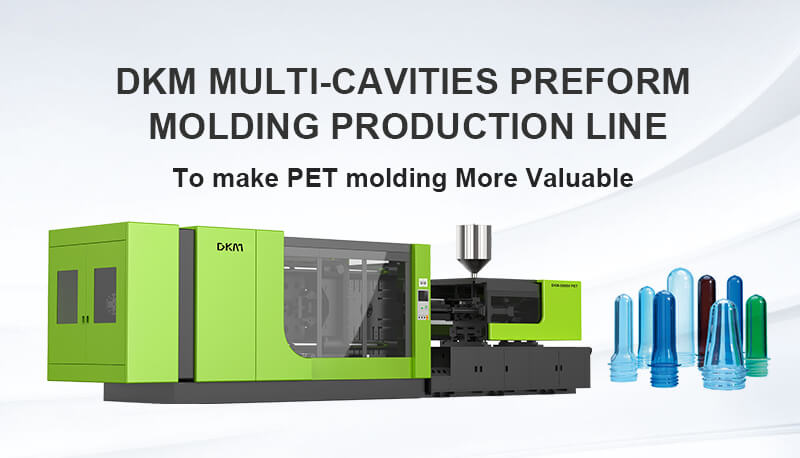

DKM is a professional PET blowing machine manufacturer, owns 35+ technology engineers, professional in (data analysis and structural optimization. With spirit of the craftsman, to manufacture our product elaborately, we never be easily satisfied with the status, each detail of the product achieves perfection.

DKM is aiming to make the blowing machines to achieve your efficient and profitable production.

Till now, we have already provided to more than 50 countries such as Thailand, Mexico, Pakistan, Australia, Ecuador, Spain and South Africa...

DKM PET bottle production line included:

1:Disinfection system

2:PET preform injection molding system

3:Water bottle filling system

4:Bottle package system

5:PET bottle blow molding system

Each DKM person, with strong responsibility spirit, is strict control on quality, delivery time and customer purchase experience.

We adopts Germany advanced technology to develop the SN-BL series PET high speed energy-saving full automatic bottle blowing machine with servo system for driving. It has the advantage of accurate positioning, low noise, power saving and fast speed. From 2 cavities to 8 cavities, the max. volume could be 200mL.

It's suitable for producing PET plastic containers and bottles in all shapes like carbonate-ed bottle, mineral water bottle, pesticide bottle, oil bottle, beverage bottle, medicine bottle etc.

semi-automatic computer-controlled and infrared oven heating blowing machine is designed for blowing large neck diameter 28-120mm and within 5L(PET, PPABS PMMA, PC, PS) plastic contain-ers. with the highlights of high press ure, strong clamping force, small size, low power consumption, easy operation and convenient maintenance.

As a PET bottle blow mould manufacturer, we have a variety of high-precision tooling machines which can ensure that the mold can be processed qualified at the first time. It can shorten the time you buy the blow mold, as well as shorten the cost of time.

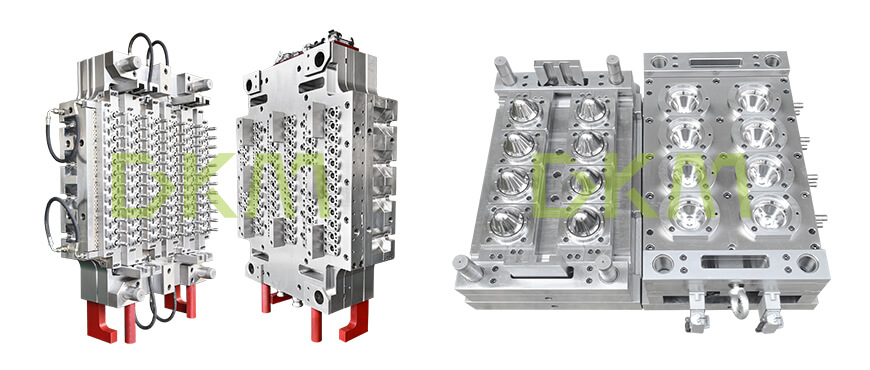

SINO Packaging Mould, a large-scale mold division, belongs to SINO MOULD. It has been devoted to the research and development and manufacture of multi-cavity bottle preform moulds. A number of talents would be introduced and huge investment in research and development every year especially in those aspects: precision injection molding, precision processing, high molding speed for shorter cycle time. Thus, SINO PET Preform Mould enjoys high reputation in the world thanks to continuous innovation and improvement. Up to now, we have delivered more than 6000 sets of PET bottle preform moulds highly recognized by customers. In addition, SINOPK can also provide technical support and solutions for high-capacity PET bottle preform production line for the bottle industry

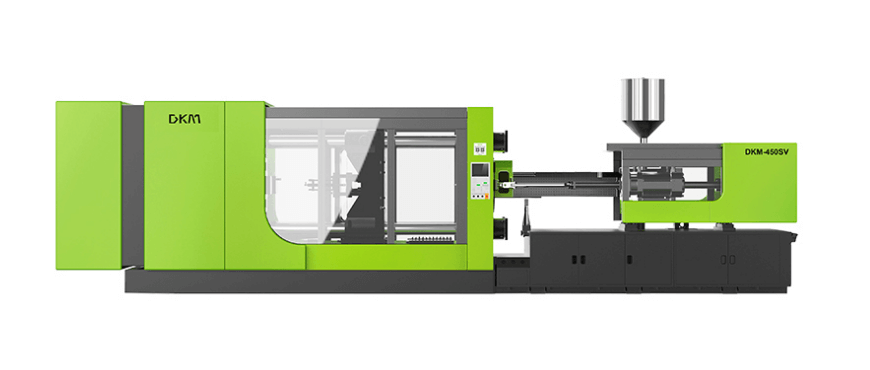

Quick response - PET injection machine adopts high precision single cylinder injection system, suitable for PET molding lines, with low-inertia and high response speed.

Perfect precision - use KEBA controller and high performance clamping platen, injection screw precision position setting to 0.01mm

Easy to install - robot system for PET multi cavity mould, the robot base screw holes optional.

High security - equipment maintenance remind, cold start screw alarm and self-protect and low oil position alarm.

Clamping force - from 1100 KN to 6500 KN

Ready European standard connector for robot.

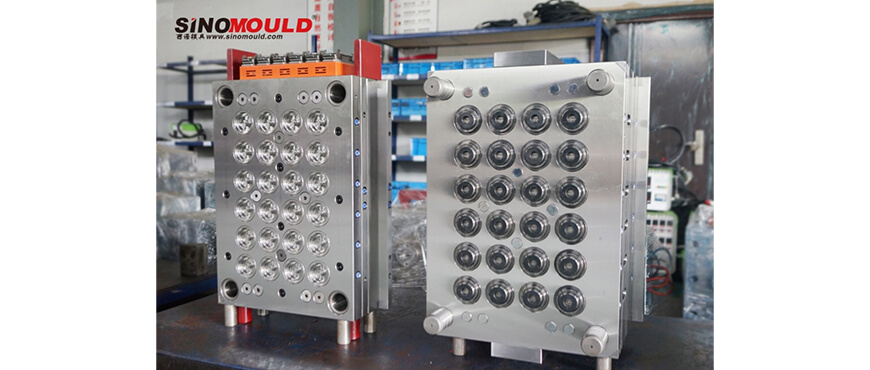

SINO Mould is the famous Chinese cap mould maker which specialized in producing water cap mould and bottle cap mould. We can offer you different kinds of plastic cap mould solutions, eg, automatic unscrewing ejection cap solution, bi-injection system cap solution, complex flip top cap solution and irregular shape design cap solution.

We have long history and rich experience in making bottle cap mold. With the advantage of Stavax S420 for core and cavity, P20 for mould base, our cap molds have the longer mould life and durability.

In order to become the biggest bottle cap mould maker in china, we devoted to keeping high quality in cap molds. Our flip-top cap mould used Stavax S420 stainless steel, tempered with HRC55+/-2 with maximum mould life. We also have various shape design and size for your special plastic cap mold demand.

SINO Mould is your best choice if you are looking for a credible cap mould company. We could offer you high quality and reasonable price mould.

Please contact us. We offer you not only a mould, but a fine solution…….

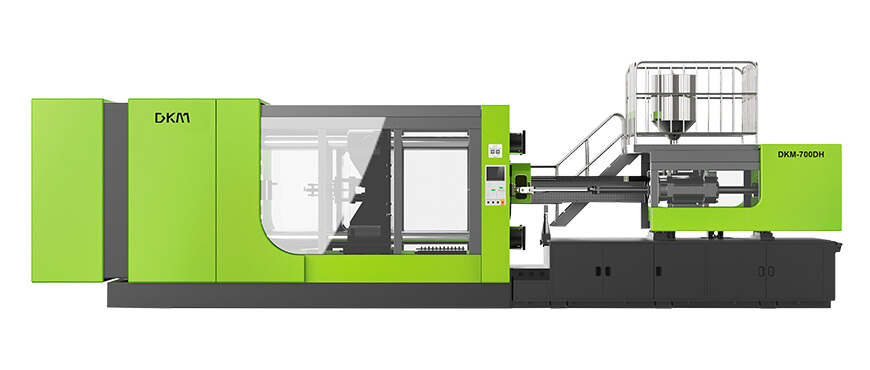

High Energy Saving – servo motor control system only delivers hydraulic oil as it is needed for various functions, which prevents unnecessary generation of heat and substantially reduces oil cooling requirements.

Long Working Life – high efficiency, lower oil temperature, making oil tank much smaller and service life of hydraulic oil and elements much longer.

Molding Stability - injection carriage linear guide with high precision and speed for injection, it avoids the barrel drop down, make sure the injection is stable and precise.

Compact Size – injection moulding machine with a small footprint and low height.

Clamping Force - from 800 KN to 40000 KN

Ready European standard connector for robot.

Suitable for food container, spoon and fork, IML project …

SINO Mould is the famous Chinese cap mould maker which specialized in producing water cap mould and bottle cap mould. We can offer you different kinds of plastic cap mould solutions, eg, automatic unscrewing ejection cap solution, bi-injection system cap solution, complex flip top cap solution and irregular shape design cap solution.

We have long history and rich experience in making bottle cap mold. With the advantage of Stavax S420 for core and cavity, P20 for mould base, our cap molds have the longer mould life and durability.

In order to become the biggest bottle cap mould maker in china, we devoted to keeping high quality in cap molds. Our flip-top cap mould used Stavax S420 stainless steel, tempered with HRC55+/-2 with maximum mould life. We also have various shape design and size for your special plastic cap mold demand.

SINO Mould is your best choice if you are looking for a credible cap mould company. We could offer you high quality and reasonable price mould.

Please contact us. We offer you not only a mould, but a fine solution…….