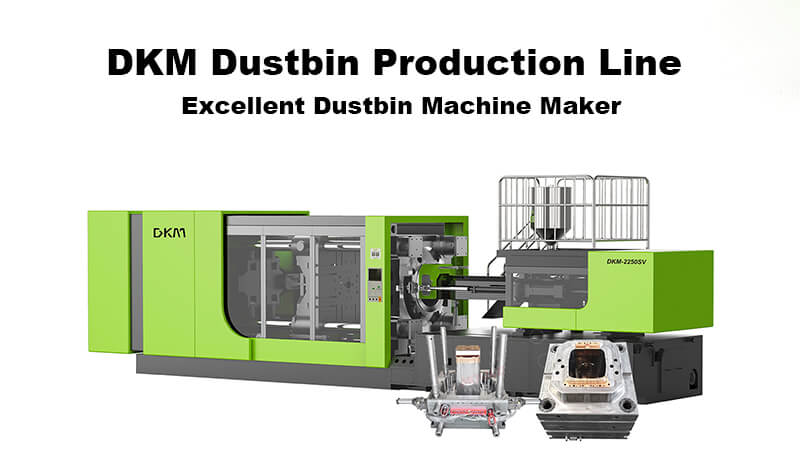

Garbage sorting has been a hot topic this year, and the demand for garbage cans will continue to grow for a long time to come. Among them, plastic garbage trash cans have more obvious advantages than other materials product , such as durability, strong impact resistance, recyclability and high environmental performance.

DKM as the experienced garbage bin production line manufactuer,we engaged in providing custom

one-stop shopping service, which is not limited to the mould, injection machine and auxiliary equipment manufacturing and supplying

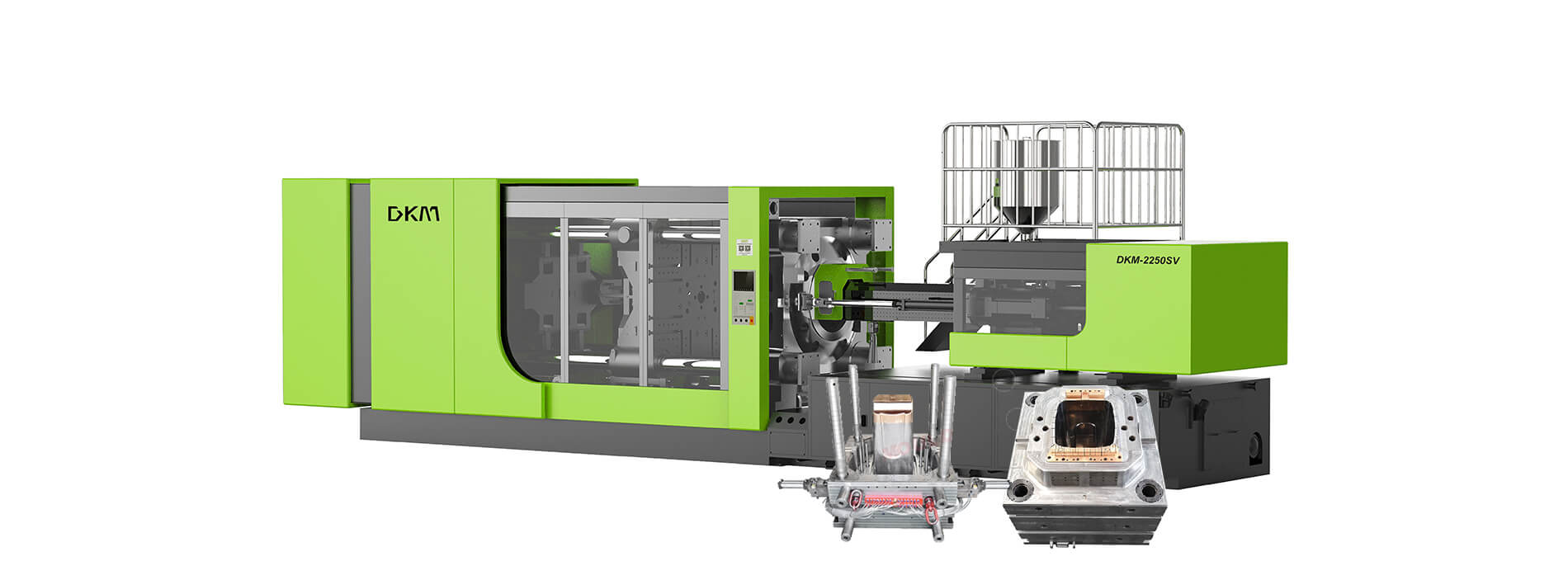

Improved efficiency - Injection carriage linear guide with high precision and speed for injection even with high shot volumes, which enables you to produce large parts cost-effectively and energy-efficiently.

Triple protection - Mechanical & electronic & hydraulic safety protect for huge injection molding machine to avoid tremendous accidents.

Short cycle times - thanks to powerful injection unit, parallel function for mold open & ejection and cooling & charging.

Easy operation - 10 language available with KEBA computer, easy nozzle center adjusting function, multi-section mold opening program.

Clamping force - from 800 kN to 40,000 kN

Ready European standard connector for robot.

Suitable for industrial items and large parts(large box containers & pallets), automotive big parts(Bumper, Air Spoiler…), home appliance beach(air conditioner, washing machine), plastic household(chairs & tables)...

We can offer customized large-scale injection machines according to your special requirements.

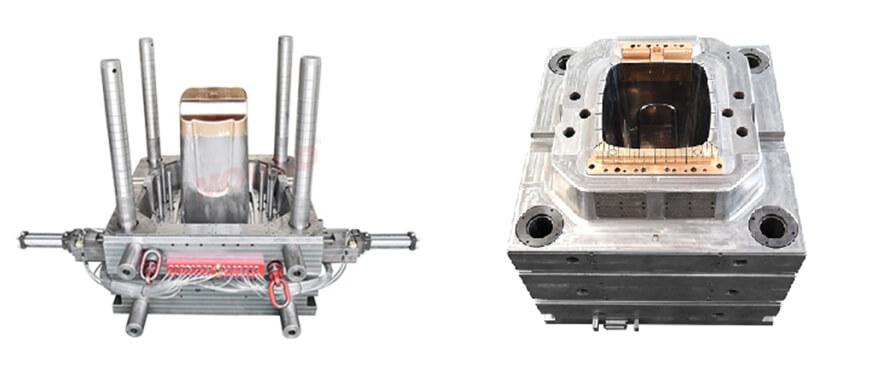

Use BeCu material and specific area waterway design along the mouth rib, which can quickly improve the heat transfer speed and reduce the cycle time.

Advanced large equipment such as gantry milling, etc., can meet the production requirements of large molds, the heaviest mold can be more than 50T;

Anti-eccentricity mechanism design to ensure the uniform thickness

High precision processing technology, precision mold positioning, to prevent mold eccentricity in the injection process;

It has a good exhaust system, easy to injection molding

The logo inserts can be exchanged in the machine without moving the mold, which is convenient and fast;

Before sales service: provide one-stop shopping service help customer to select the most suitable machine and related auxiliary machine

In sales service:We will helps customer to make the workshop display, such like electricity line and cooling water installation.

After sales:We will send engineers to help customer make the machine installation operation and skill training to the workers in the workshop.

During the 13 month guarantee time, We offer all the damaged parts free of charge and response to parts assembling.

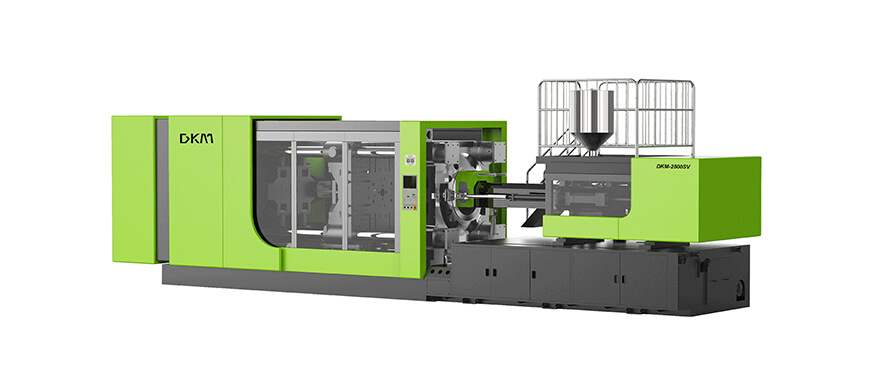

DKM 3350Ton Two Platen Injection Molding Machine with Super Trash Can Mould makes it easy to produce trash can of such a large volume and picking robot helps automatic production.

We are not just super in size, DKM 1100L Super Trash Can Production Line brings you superior production experience!