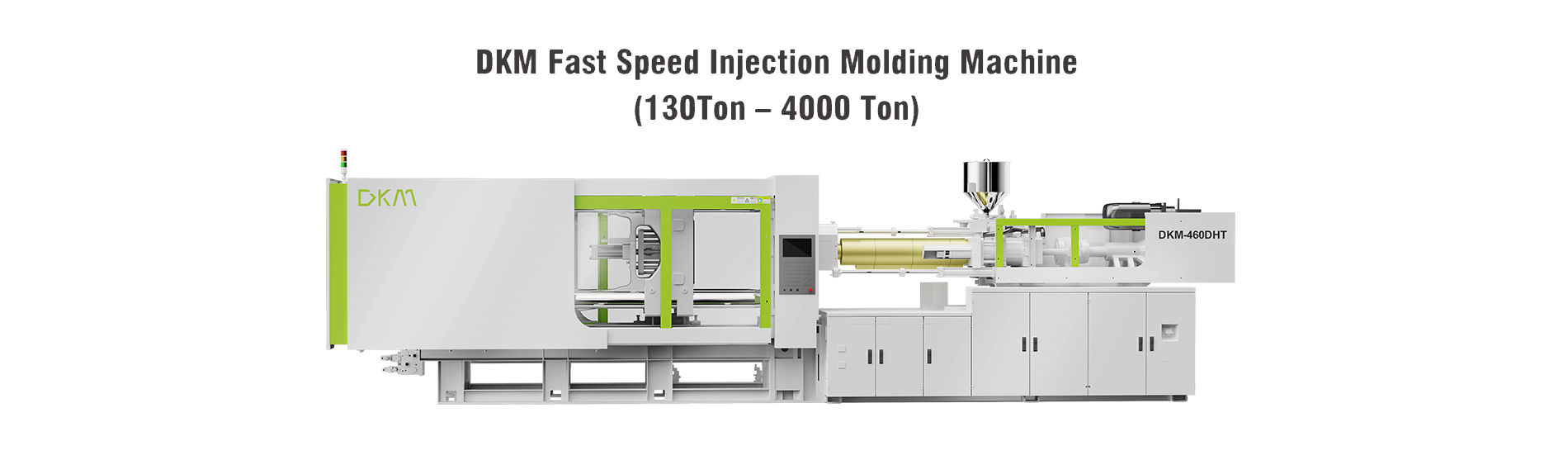

DKM-DH series injection machine (DKM Lightning Machine) is updated with electrical pre plastic charging system and self-locking nozzle based on DKM servo motor machine for shorter cycles – 30%-50%, achieving quicker payback. It’s ideal for items such as daily necessities, paint buckets, turnover boxes, etc., which require high output and short cycle.Clamping force from 1,300kN to 33,500kN.

The DKM-DH series is a range of high-speed injection molding machines designed to produce thin-walled products. The machines in this series have a clamping force ranging from 250mm/s for 130Ton -650Ton and 150mm/s for 850Ton – 4000Ton, providing a wide range of options to suit different production needs.

One of the critical features of the DKM-DH series is its high-speed injection capability, allowing for rapid and efficient production of thin-walled products with precise dimensional control. The machines in this series are equipped with advanced control systems that enable fast and accurate injection as well as a high-speed response to changing process conditions.

To further enhance their performance, the DKM-DH series machines have various user-friendly features, such as an intuitive HMI interface, automated mold adjustment, and a remote monitoring system. These features make the machines easy to operate and maintain while improving production efficiency and reducing downtime.

The DKM-DH series injection molding machine is highly versatile. It can be used to produce a wide range of thin-wall products, including food packaging, cosmetic containers, and electronic components. The machines are also compatible with a variety of materials, including PP, PE, PS, and PET.

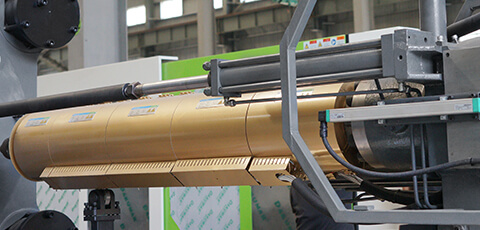

With electrical pre plastic charging system, DKM-DH Injection Molding Machine realize fast and precise injection molding.

Whether you are a beginner or an experienced user, you can follow the following steps to achieve the best results.

Before using the DKM-DH injection machine, it must be appropriately set up and ready to use. To do this, follow these steps:

1.1) First, ensure the power supply is connected and turned on.

1.2) Next, check that the hydraulic oil level is correct. If it is not, add hydraulic oil as necessary.

1.3) Check that the water cooling system is functioning correctly. The water temperature should be between 20°C and 30°C.

1.4) set the temperature controller to the desired temperature for the plastic used.

Once the machine is set up and ready to use, it is time to prepare the mold. Follow these steps:

2.1) Clean the mold thoroughly to ensure that no dirt or debris could affect the quality of the final product.

2.2) Apply a release agent to the mold to prevent the plastic from sticking.

2.3) Install the mold onto the machine and ensure it is properly aligned.

The next step is to load the plastic into the machine. Follow these steps:

3.1) Place the plastic into small pieces in the hopper.

3.2) Turn on the machine and wait for the plastic to melt. This can take anywhere from a few minutes to several hours, depending on the type of plastic and the machine's temperature.

3.3) Once the plastic has melted, it will be injected into the mold through the nozzle.

Now that the plastic is loaded and the mold is in place, it is time to start the injection molding process. Follow these steps:

4.1) Close the mold and activate the injection unit.

4.2) The plastic will be injected into the mold under high pressure. The pressure and injection time can be adjusted based on the type of plastic and the desired product.

4.3) Once the plastic has cooled and solidified, the mold can be opened, and the finished product can be removed.

After using the machine, it is essential to clean it properly to ensure it continues functioning properly. Follow these steps:

5.1) Turn off the machine and disconnect the power supply.

5.2) Clean the mold and injection unit thoroughly to remove any remaining plastic.

5.3) Check and clean the filter to ensure it is debris-free.

5.4) Finally, wipe down the machine with a clean cloth to remove any dirt or debris.

Following these steps, you can effectively use the DKM-DH injection machine to create high-quality plastic products. It is essential always to use caution when working with the machine and to follow all safety guidelines to prevent injury.

There are several reasons to choose this injection molding machine. However, some of the most considered ones are:

Please contact us directly and we will develop the right injection molding machine solution for you according to your needs.

If you are considering using the DKM-DH series of high-speed injection molding machines, there are several important factors to remember. Here are some key things you need to know about this machine series:

The DKM-DH series machines range in capacity from 130Ton-3350Ton and provide a wide range of clamping forces to meet various production needs. When selecting a machine, it is essential to consider the capacity and clamping power required for the specific products being produced.

The DKM-DH series machines are designed for high-speed injection molding, with fast injection speeds and high pressure. This enables shorter cycle times and higher productivity, but it also requires careful attention to the machine settings and safety precautions to ensure proper operation.

The DKM-DH series machines are designed for precision injection molding, focusing on producing high-quality products with minimal defects. The machines have advanced injection control systems and professional single-cylinder injection systems with servo valves to ensure precise quality and faster response times.

The DKM-DH series machines can be customized according to specific production needs. This allows for greater flexibility and efficiency in the production process, with machines tailored to the product's specific requirements.

The DKM-DH series machines require regular maintenance and lubrication to ensure optimal performance and longevity. It is essential to follow the manufacturer's recommended maintenance schedule and to keep the machine clean and free from debris to prevent damage to the components.

The DKM-DH series injection molding machine is a powerful and complex piece of equipment that requires careful attention to safety precautions. Proper training and certification in injection molding machines are recommended before operating the machine and users should always follow the manufacturer's recommended safety procedures.

If you are considering purchasing a DKM-DH series high-speed injection molding machine, there are several reasons why you should consider DKM as your supplier.

DKM offers competitive pricing for the DKM-DH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

In conclusion, the DKM-DH series of high-speed injection molding machines is a versatile and efficient option for producing thin-walled products with precision and speed. The machines offer a range of customization options and are designed for high-quality and reliable performance, making them an excellent choice for businesses of all sizes.

When considering the purchase of a DKM-DH series machine, it is crucial to keep in mind the specific needs of your production process and to work with a reputable supplier such as DKM offers a range of benefits, including experience and expertise, customization and flexibility, quality and performance, service and support, and competitive pricing.

Contact us to help you choose the suitable machine and complete injection molding solutions.