During preform injection molding step, the below equipment and auxiliary equipment would be applied.

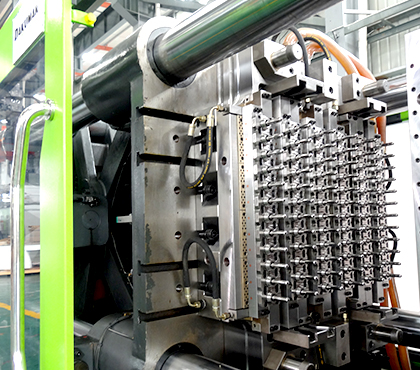

1.PET preform injection molding machine which is specially designed suitable for PET preform manufacture.

2.PET preform mould with hot runner valve gate system, mould cavity could be 8 cavity, 12 cavity, 16 cavity, 24 cavity, 32 cavity,48 cavity,72 cavity,96 cavity, 144 cavity...

3.Three in One equipment. Before preform injection molding, the PET plastic raw material will go for Three in One equipment first with the function material feeding, drying and dehumidifying.

4.Low pressure air compressor set, including air compressor, air dryer, air tank and air filter. this is for preform mould hot runner valve gate system.

5.Cooling tower and chiller for cooling purpose. The cooling facility is very important for preform injection molding.

6.Mould dehumidifier: With low temperature cooling in the molding, mould dehumidifier is needed for removing the sweat.

7.Color doser: this is required for making preform with different color.

8.Crusher: crusher is the optional accessory for material recycling function.

The equipment used in blowing step as follows:

1.Blowing mould: the blowing mould cavity number could be single cavity, 2 cavity, 3 cavity, 4 cavity, 6 cavity, 8 cavity...

2.Blowing machine: semi-automatic blowing and fully automatic machine can be chosen depends on BPH productivity requirement,the output could reach 8500 bottles per hour.

3.Air compressor set: low pressure and high pressure air compressor would be applied with air tank, air dryer and filter for blowing step

4.Chiller should be used for fully automatic blowing .

Dakumar supplies Turnkey solution for PET bottle production line for around 20 years,with know-how technology and years’ experience, we will support to optimize your investment with high performance and long run profit.