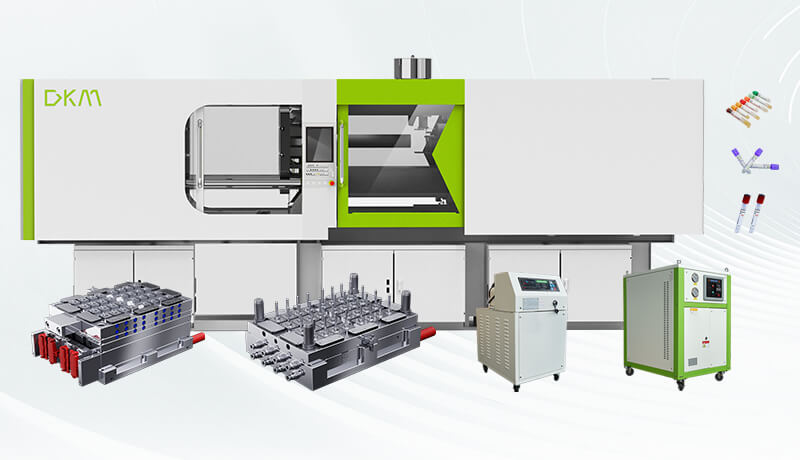

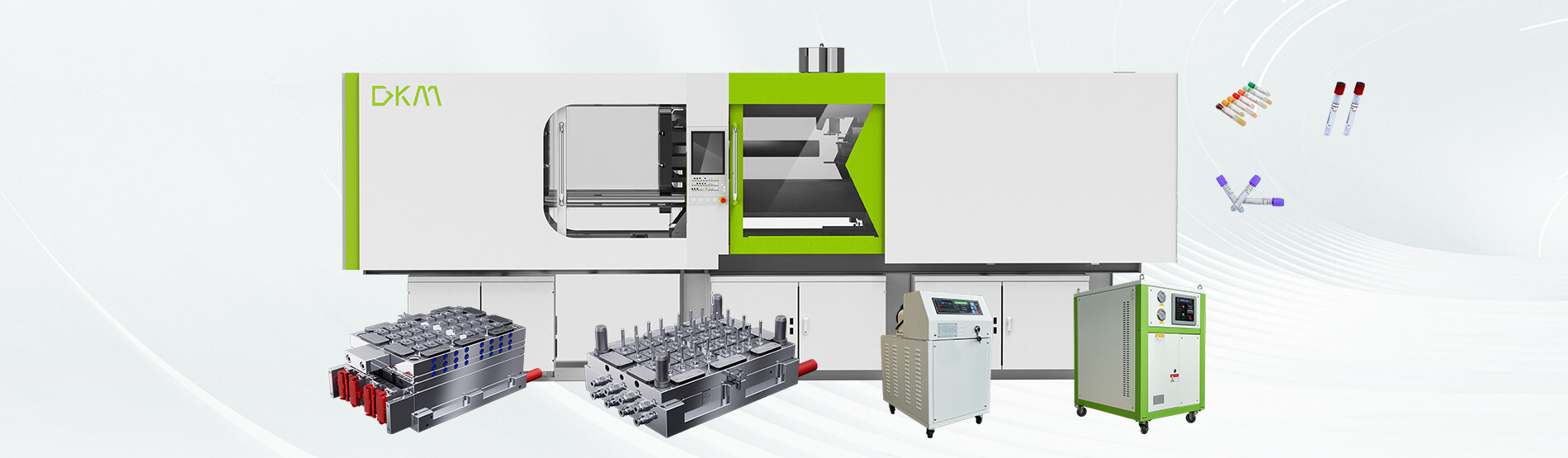

DKM offers intelligent &. high efficient PET Blood Collection Test Tube Manufacturing Line with the turnkey solutions. If you are looking for the reliable and professional PET blood test tube producing line, then you are at right place. Please check DKM outstanding PET blood collection tube produce line and contact us.

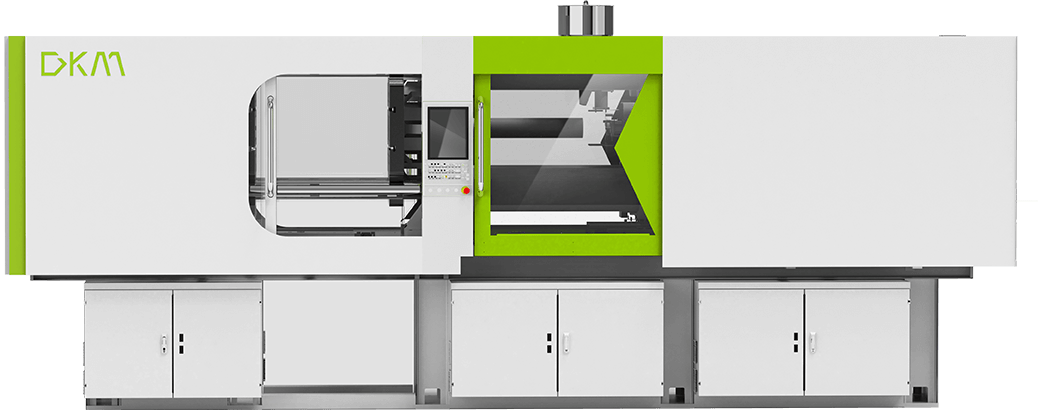

High speed, precision and stable running guarantee the efficient and large production capacity.

High speed, precision and stable running guarantee the efficient and large production capacity.

High quality injection screw especially for PET material, electric injection system with accurate shot weight controlling.

High quality injection screw especially for PET material, electric injection system with accurate shot weight controlling.

Special designed for PET testing tube injection molding, more then 10 years continuous optimization.

Special designed for PET testing tube injection molding, more then 10 years continuous optimization.

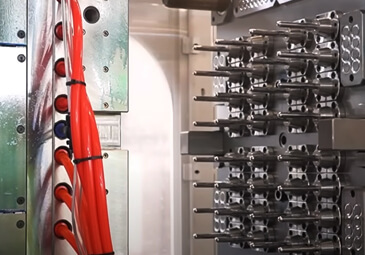

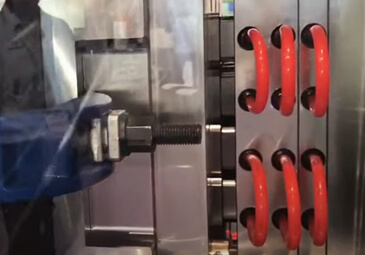

![]() Independent self-locking structure-accurate locked and easy for maintenance.

Independent self-locking structure-accurate locked and easy for maintenance.

![]() Many year mould design optimizing made a perfection mould.

Many year mould design optimizing made a perfection mould.

![]() Special steel selection and special heat treatment till HRC 55.

Special steel selection and special heat treatment till HRC 55.

![]() High precision grinding ensure no eccentricity.

High precision grinding ensure no eccentricity.

![]() Rigorous QC ensure the dimension of mould components tolerance ±0.005mm.

Rigorous QC ensure the dimension of mould components tolerance ±0.005mm.

![]() Cavities Nr. from 32-72 cavities.

Cavities Nr. from 32-72 cavities.

Product Material:PET

Mold Size: 600*400*450mm (mm)

Cavity: 32 cavities

Description: Sino provides 8-144 cavities blood collection tube mould, adopting high hardness, high clean quality steel material, which ensures that the blood tube is clean enough; with Anole needle valve runner system design, to reduce the traces of the fusion of raw materials. Our blood tube is high-quality and precise, with a high qualification rate and no defective products.

![]() Based on your annual production quantity demand, we will suggest the most reasonable Blood Collection Test machines, molds and related equipment, and send you the outstanding project quotation book with all the budget. After all the necessary detailed negotiation and confirmation.

Based on your annual production quantity demand, we will suggest the most reasonable Blood Collection Test machines, molds and related equipment, and send you the outstanding project quotation book with all the budget. After all the necessary detailed negotiation and confirmation.

![]() In the 2nd step, we will work out your workshop's detailed layout for electricity water airline, machines and equipment positioning, PET raw material keeping and treatment warehouse, and ready-made blood tube warehouse.

In the 2nd step, we will work out your workshop's detailed layout for electricity water airline, machines and equipment positioning, PET raw material keeping and treatment warehouse, and ready-made blood tube warehouse.

![]() In the 3rd step, we will start the machines, molds and all equipment production. When these are ready, we will test them in our facility until everything becomes very smooth and stable.

In the 3rd step, we will start the machines, molds and all equipment production. When these are ready, we will test them in our facility until everything becomes very smooth and stable.

![]() The 4th step is delivery and when all the machines arrive at your workshop, we will send our service engineers to your SPOT for assembling, operation, and training....until your normal mass production.

The 4th step is delivery and when all the machines arrive at your workshop, we will send our service engineers to your SPOT for assembling, operation, and training....until your normal mass production.

Here are videos of some of our blood collection test tube manufacturing