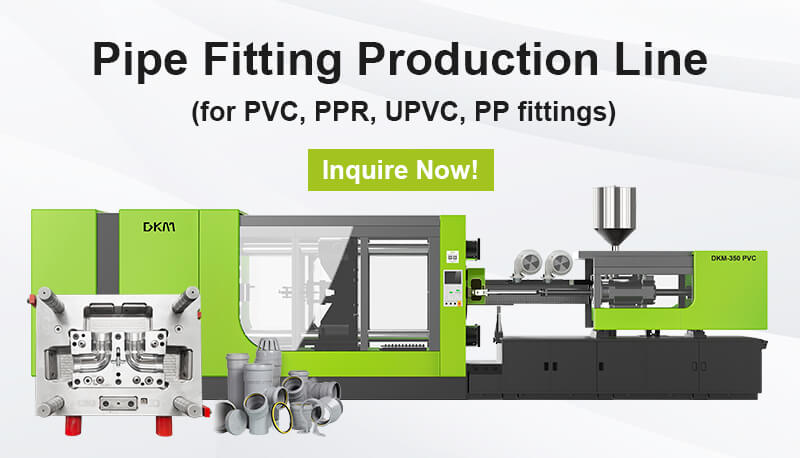

Pipe Fitting Production Line

DKM cooperate with SINO MOULD as an expert provide full set of high quality and professional pipe fitting injection molding line services, with decades of experiences in PVC and PPR pipe fitting connector plastic injection molding solution, including pipe fitting injection machine, pipe fitting molds, and related accessories.

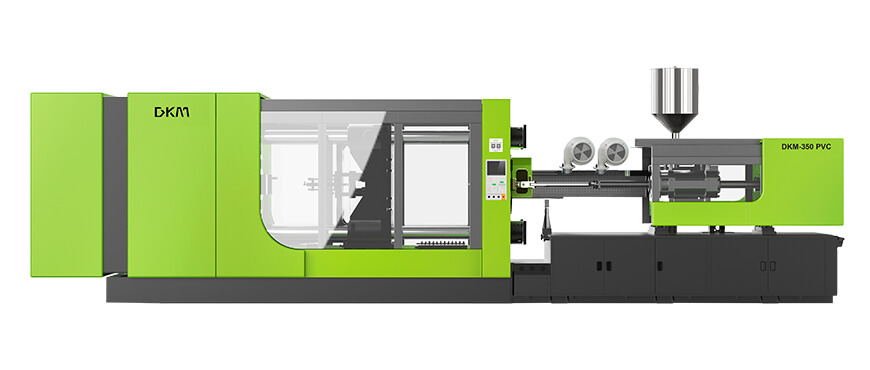

Pipe Fitting Injection Molding Machine Perfect Design- Precise temperature control system,PVC screw barrel, PVC high-efficiency cooling fan and multi-core pulling to meet the complex action requirements of PVC. PVC controller unit - using PVC core pull action to connect signal setting and PVC material temperature setting reserved program. Individual solution - optional PVC large frame, optional PVC powder and granules.

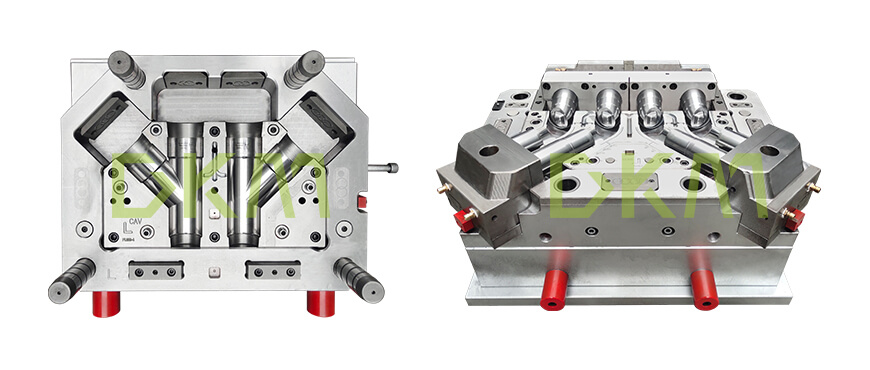

Pipe Fitting Mould DKM have rich experience in making pipe fitting mold, such as PVC pipe fitting mold, PPR pipe fitting mold, U-PVC pipe fitting mold, and any other special fitting mold DKM have around 30-50 designer design and analyze the product & mould with professional suggestion for clients. DKM QC department will be responsibility for every tooling step and every dimension even for inserts.

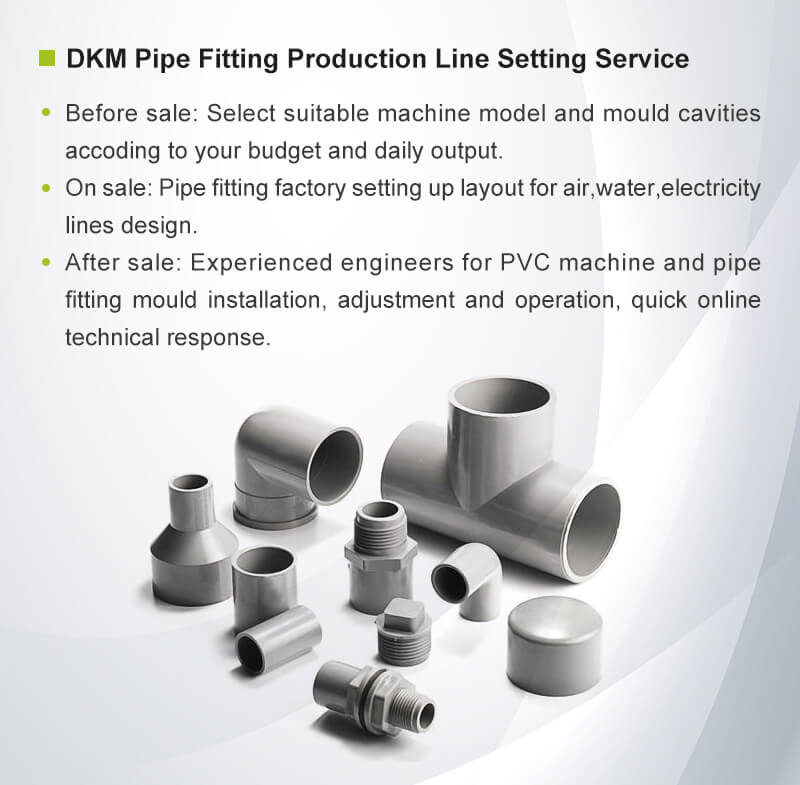

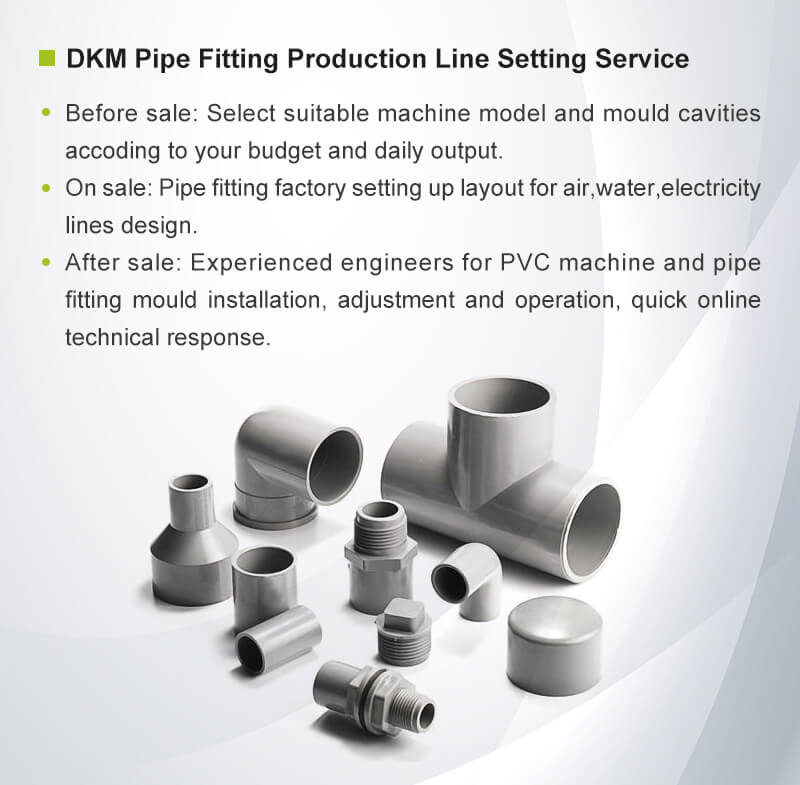

DKM Pipe Fitting Production Line Setting Service

Before sale: Select suitable machine model and mould cavities accoding to your budget and daily output On sale: Pipe fitting factory setting up layout for air,water,electricity lines design. After sale: Experienced engineers for PVC machine and pipe fitting mould installation, adjustment and operation, quick online technical response.

Pipe Fitting Injection Molding Video

If you have any interest on DKM Pipe Fitting Production Line, welcome to contact us.