DKM injection molding machines range among the top 3 brands for two-platen injection molding machines with high precision tolerance, which is original Italian technology. With their latest innovation, the DKM-TP Series Two-Platen Injection Molding Machine, DKM is redefining precision, efficiency, and reliability in the world of plastic manufacturing. Whether you're a seasoned industry professional or just getting started, this state-of-the-art machine is the ultimate game-changer, offering unparalleled performance and versatility. Get ready to unlock new possibilities and take your production capabilities to unprecedented heights with DKM-TP Series Two-Platen Injection Molding Machine.

The DKM-TP Series Two-Platen Injection Molding Machine is an advanced and high-performance machine designed for efficient and precise injection molding processes. It incorporates innovative features and technologies to meet the demands of various industries, such as automotive, packaging, electronics, and more.

The term "two-platen" refers to the machine's unique design, which utilizes two platens instead of the traditional three-platen system. This design offers several advantages, including improved mold opening and closing movements, enhanced stability, reduced machine footprint, and increased flexibility for larger mold sizes.

Whether you are a beginner or an experienced user, you can follow the following steps to achieve the best results.

Unpack the machine components carefully and ensure that all necessary parts are present.

Ensure that the machine is installed in a location that has proper ventilation and ample space, adhering to the manufacturer's instructions.

Connect the power supply, water source, and any necessary auxiliary equipment, such as chillers or dryers.

Conduct a comprehensive examination of the machine, carefully inspecting for any loose connections or possible problems.

Power on the machine and allow it to initialize the control system.

Familiarize yourself with the machine's control panel and user interface.

Set the appropriate language, date, and time on the control system.

Select a suitable mold for your desired product and ensure it is clean and in good condition.

Carefully mount the mold onto the machine's platen, following the specific instructions provided by the mold manufacturer.

Ensure that the mold is securely fastened and properly aligned with the machine's clamping unit.

Choose the appropriate plastic material for your product, considering factors such as strength, durability, and color requirements.

Prepare the plastic material by drying it if necessary, following the manufacturer's guidelines.

Load the plastic material into the machine's hopper or material feeding system, taking care to avoid any contamination.

Access the machine's control system and navigate to the parameter settings.

Set the desired injection molding parameters, including temperature, pressure, injection speed, and holding time, based on the material and product requirements.

Refer to the material supplier's recommendations and process guidelines for guidance on parameter settings.

Run a test cycle to validate the machine setup and parameter settings.

Monitor the injection molding process closely, observing the behavior of the molten plastic and the quality of the molded parts.

Make any necessary adjustments to the parameters to optimize the process and achieve the desired product quality.

Once the machine is in full production, monitor the process regularly to ensure consistent quality and productivity.

Conduct routine maintenance tasks as recommended by the manufacturer, including lubrication, inspection of components, and cleaning of the machine.

Always priorities safety when operating the machine.

Ensure that operators are properly trained on the machine's operation and safety procedures.

Follow all safety guidelines provided by the manufacturer and implement additional safety measures specific to your production environment.

Following these steps, you can effectively use the DKM-DH injection machine to create high-quality plastic products. It is essential always to use caution when working with the machine and to follow all safety guidelines to prevent injury.

The DKM-TP Series Two-Platen Injection Molding Machine offers several advantages compared to traditional injection molding machines. Here are some key advantages:

Please contact us directly and we will develop the right injection molding machine solution for you according to your needs.

When it comes to injection molding machines, the Machine DKM-TP Series Two-Platen Injection Molding Machine stands out with its exceptional capabilities and advanced technology. In this guide, we will delve into the key features of this machine, including its clamping unit, machine power, and more, providing you with valuable insights into its capabilities and performance.

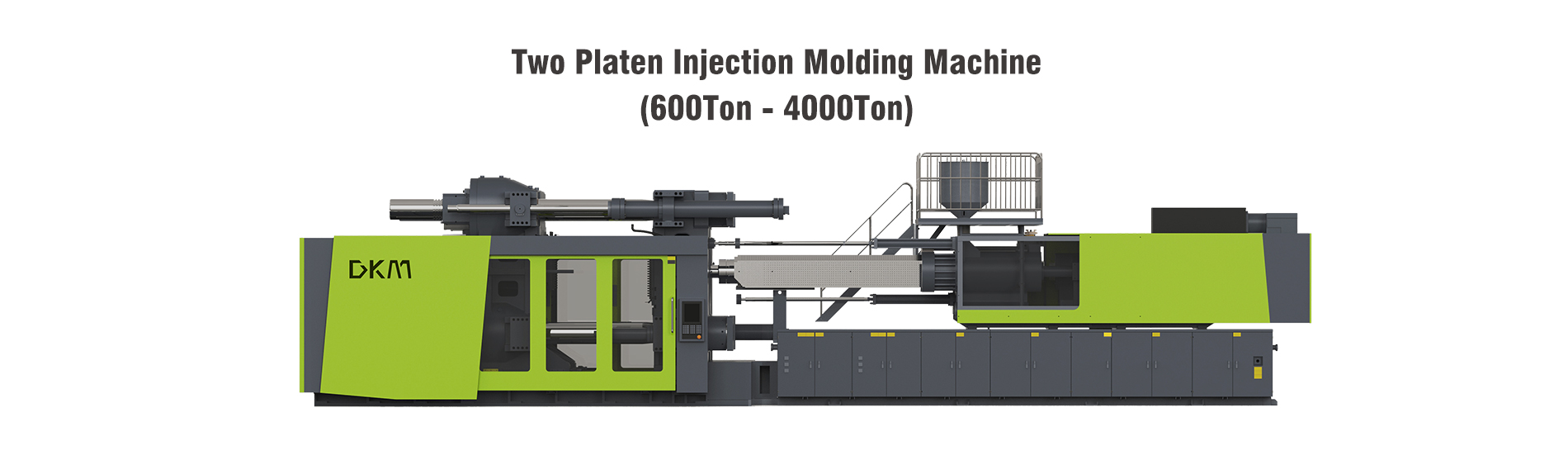

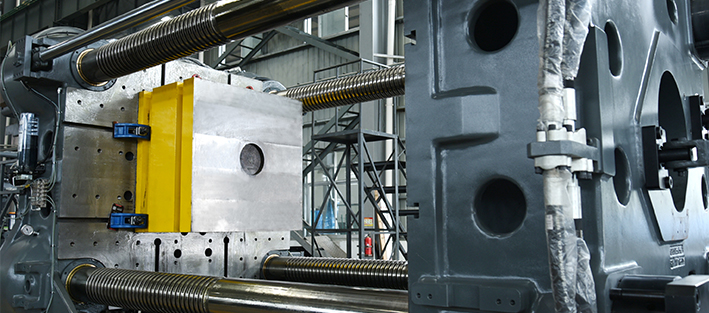

The DKM-TP Series features a unique two-plate design that sets it apart from traditional machines.

This design ensures superior clamping force distribution, resulting in enhanced precision and stability during the injection molding process.

The rigid and balanced structure of the machine minimizes distortion and warping, contributing to high-quality final products.

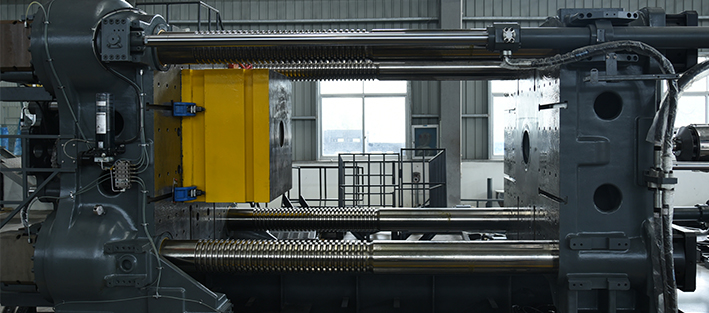

The clamping unit of the DKM-TP Series is designed to deliver optimal performance and efficiency.

It provides precise and powerful clamping force, enabling secure and reliable mold closure.

The advanced control system allows for easy adjustment of clamping parameters, ensuring consistent and accurate results.

The DKM-TP Series is equipped with high-performance servo motors, delivering exceptional power and energy efficiency.

These motors enable swift and precise movements, reducing cycle times and maximizing productivity.

The machine's optimized design and intelligent control system contribute to its impressive speed and performance, making it ideal for high-volume production.

The injection unit of the DKM-TP Series is designed to meet the diverse needs of manufacturers across various industries.

It offers a wide range of injection capacities and pressures, allowing for versatility in producing both large and small plastic parts.

The precise control of injection variables such as temperature, pressure, and injection speed ensures consistent and high-quality output.

The DKM-TP Series is designed with an advanced control system that enables operators to have complete authority over the injection molding process.

Its user-friendly interface provides effortless parameter adjustments, real-time monitoring of vital variables, and accurate control throughout the production cycle.

With advanced features like data logging and analysis, the control system facilitates process optimization, ensuring optimal efficiency and quality.

Safety is a top priority, and the DKM-TP Series incorporates advanced safety features to protect both operators and the machine.

Comprehensive safety guards, emergency stop buttons, and automatic fault detection systems ensure a secure operating environment, minimizing the risk of accidents.

DKM, a prominent manufacturer of injection molding machines, distinguishes itself in the industry not just for its outstanding machines, but also for the extensive services and support it offers to its customers. In this guide, we will showcase the unique characteristics of DKM's services and expertise, highlighting what makes them stand out from other companies in the market.

DKM offers competitive pricing for the DKM-DH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

In conclusion, Dakumar DKM-TP Series Two-Platen Injection Molding Machine proves to be a game changer in the industry. Its cutting-edge features, including the two-platen design, high-speed operation, versatility in applications, advanced control system, energy efficiency, enhanced safety features, and customization options, make it a standout choice for manufacturers. Dakumar's commitment to providing unparalleled services, expertise, and customer support further solidifies their position as a leading manufacturer. With their extensive industry experience, global presence, and dedication to innovation, Dakumar sets itself apart from other companies by offering comprehensive solutions tailored to meet the unique needs of their customers. By choosing Dakumar, manufacturers can achieve superior quality, efficiency, and success in their injection molding processes.

Contact us to help you choose the suitable machine and complete injection molding solutions.