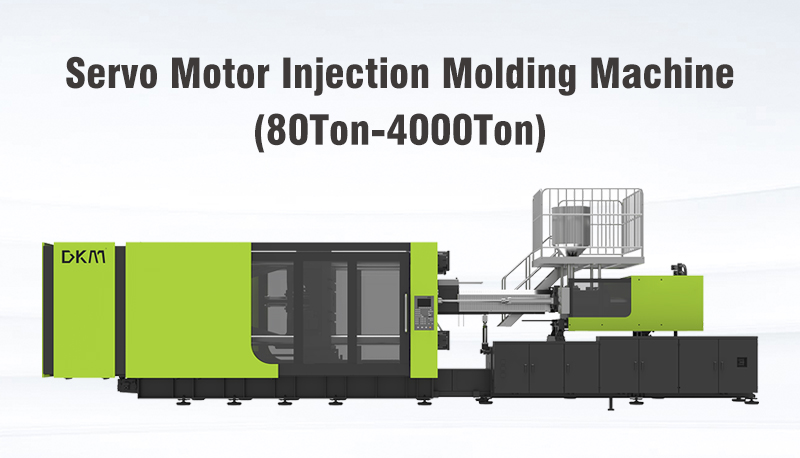

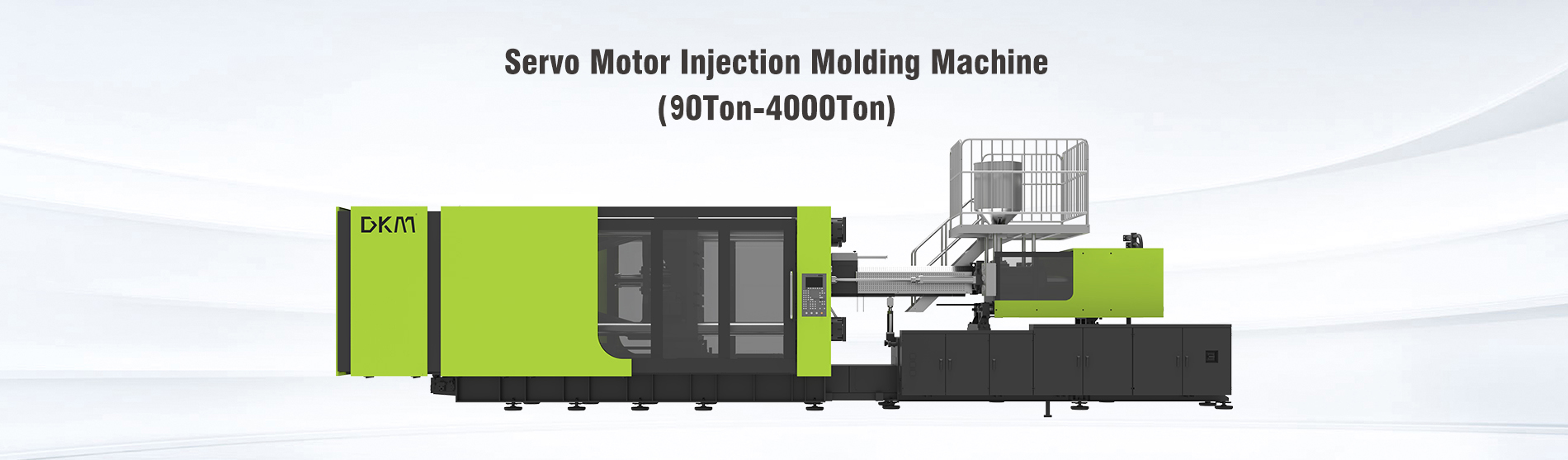

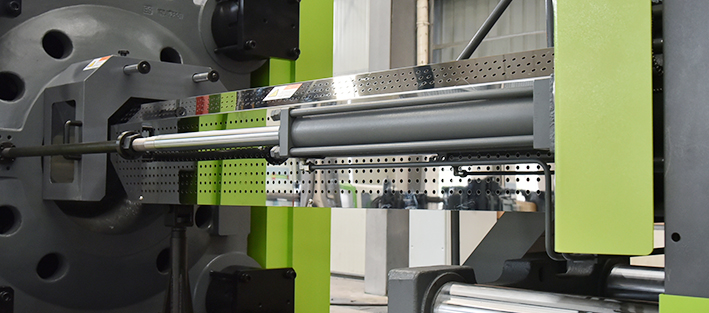

With our cutting-edge Servo Motor Injection Molding Machines, spanning from 90 to 4000 ton, developed to suit all your plastic injection molding needs, welcome to the world of advanced production. Our machines provide unmatched efficiency, dependability, and versatility thanks to cutting-edge technology and precise engineering, ensuring that your manufacturing processes reach new levels of productivity and perfection. With our sector-leading solutions, which provide top-tier performance for all your manufacturing needs, embrace the future of injection molding.

Our product portfolio, which covers loads between 130 and 4000 ton, providing a comprehensive solution for all of your injection molding needs. These devices, which make use of servo motor technology, raise the bar for production efficiency with their unrivalled precision, speed, and energy economy. Our Servo Motor Molding Machines are the perfect choice for your manufacturing operations, whether you're producing little components or big-ticket items. They are made to operate superbly and to be dependable and versatile. You can see the future of injection molding with our cutting-edge solutions, which are designed to boost your production and grow your company. Here are a few qualities to consider.

Servo Motor Injection Molding Machines showcase their remarkable capabilities and efficiency. The integration of servo motor technology enables precise and dynamic control over the injection process, resulting in consistent and high-quality outputs. These machines offer rapid injection speeds, minimizing cycle times and maximizing productivity. Their energy-efficient design also optimizes power use, cutting down on operating expenses. They are appropriate for a variety of sectors and applications because to their adaptability, which allows them to accommodate a wide range of plastic materials. Operators will appreciate the user-friendly interface and advanced control system, allowing for easy parameter adjustments and monitoring. Safety features are also incorporated to ensure a secure working environment. Whether you require small-scale production or large-scale manufacturing, our servo motor plastic machine delivers exceptional performance and reliability, empowering you to meet your production goals efficiently and effectively.

Whether you are a beginner or an experienced user, you can follow the following steps to achieve the best results.

a. Make sure the machine is tidy and free of any debris or impediments.

b. Verify that all safety barriers and locks are in place and working properly.

c. Verify that the required mold, raw material, and auxiliary equipment are ready for use.

a. Connect the machine to a reliable power source.

b. Switch on the main power supply and auxiliary systems (such as the hydraulic system and cooling system).

a. Carefully mount the mold onto the machine's platens, following the manufacturer's guidelines.

b. Securely fasten the mold using appropriate clamping mechanisms.

c. Ensure that the mold alignment is correct and that all mold components are properly installed.

a. Access the machine's control panel or interface.

b. Set the desired injection parameters, such as injection speed, pressure, and holding time, based on the specific requirements of the product and material being used.

c. Configure the temperature settings for the barrel, nozzle, and mold heating zones.

a. Prepare the raw material by ensuring it is properly dried and free from contamination.

b. Open the machine's hopper and pour the required amount of material into it.

c. Close the hopper securely to prevent material spillage.

a. Initiate the automatic or manual mode based on your preference and experience.

b. Start the machine's operation, and closely monitor the injection process for any abnormalities.

c. Adjust the parameters as needed to achieve the desired product quality and production efficiency.

a. Allow the injection molding process to complete as per the specified cycle time.

b. Once the injection is complete, activate the mold opening mechanism to release the molded part.

c. Carefully remove the part from the mold, ensuring proper handling to avoid damage or injury.

a. After completing the production run, clean the machine thoroughly to remove any residual material or contaminants.

b. Perform routine maintenance tasks as recommended by the manufacturer, such as lubricating moving parts and inspecting hydraulic systems.

c. Switch off the machine, auxiliary systems, and main power supply.

The advantages of using a Servo Motor Injection Molding Machine (ranging from 80 tons to 4000 tons) are numerous and can significantly enhance your manufacturing operations. Here are the key advantages in detail:

Please contact us directly and we will develop the right injection molding machine solution for you according to your needs.

When working with a Servo Motor Injection Molding Machine (80Ton-4000Ton), there are several key aspects you should be aware of:

Familiarize yourself with the specific specifications of the machine you are operating, including its tonnage range (80 tons to 4000 tons) and other relevant parameters such as maximum injection pressure, injection speed, and mold opening stroke. Understanding these specifications will help you optimize your production process.

Gain a comprehensive understanding of the servo motor technology employed in the machine. Servo motors offer precise control, energy efficiency, and improved responsiveness, enabling enhanced performance and cost savings compared to traditional hydraulic systems.

Ensure that the mold you are using is compatible with the machine's specifications. Consider factors such as mold size, clamping force requirements, and any specific mold features or accessories needed for proper installation and operation.

Different Plastic injection molding machines are designed to process specific types of plastic materials. Verify that the machine is suitable for the type of material you intend to use. Additionally, understand the material's melt temperature, flow characteristics, and any specific processing requirements to optimize the injection process.

Understand the operating procedures and controls specific to the machine you are working with. Learn how to set and adjust parameters such as injection speed, pressure, holding time, and temperature settings. Additionally, become familiar with the machine's control panel, interface, and any available automation features.

Regular maintenance is essential for the smooth operation of the machine. For normal maintenance chores like lubrication, filter changes, and hydraulic system check, according to the manufacturer's instructions. Learn how to identify and fix any problems that might occur while operating by being familiar with standard troubleshooting techniques.

Ensure that operators receive appropriate training on the operation, maintenance, and safety aspects of the machine. Utilise the tools at your disposal, such as user manuals, technical assistance, and training courses offered by the machine's manufacturer, to expand your understanding and competence.

Buying a Servo Motor Injection Molding Machine (80Ton-4000Ton) offers several compelling reasons to consider. Here are the key benefits and advantages:

DKM offers competitive pricing for the DKM-DH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

In conclusion, this machine is a highly advantageous choice for businesses seeking advanced technology, versatility, and reliability in their manufacturing operations. With its wide range of tonnage options, the machine can caters to various project sizes and offers scalability for future growth. The incorporation of advanced technology, such as servo motor drive systems and high-speed injection capabilities, ensures exceptional performance, energy efficiency, and precise control. The user-friendly interface and controls make operation intuitive and efficient, while DKM's comprehensive support and service guarantee a smooth experience from installation to ongoing maintenance. Furthermore, the cost-effectiveness of the machine, along with its long-lasting quality, makes it a smart investment for businesses aiming to maximize productivity and profitability. Overall, choosing this machine provides a reliable and efficient solution to meet diverse production needs and achieve success in the competitive manufacturing industry.

Contact us to help you choose the suitable machine and complete injection molding solutions.