Welcome to the world of precision and power with Dakumar's exceptional range of injection molding machines! Look no farther if you want to fully realise the possibilities of plastic injection moulding. Our cutting-edge equipment, which can handle projects weighing anywhere between 200 tonnes and an incredible 1300 tonnes, offers unmatched performance and efficiency, revolutionising the way you realise your ideas.

Imagine being able to precisely generate high-quality parts while moulding complicated shapes and complex geometries. You can achieve that thanks to our selection of injection moulding machines. We have the equipment to meet your individual needs, ranging from our adaptable 200-ton machines, ideal for smaller production runs or complicated components, to our strong 130-ton machines, built to handle high-volume production.

Let’s delve in details to know more about DKM fast Speed Injection Molding Machine (200tons-1300tons).

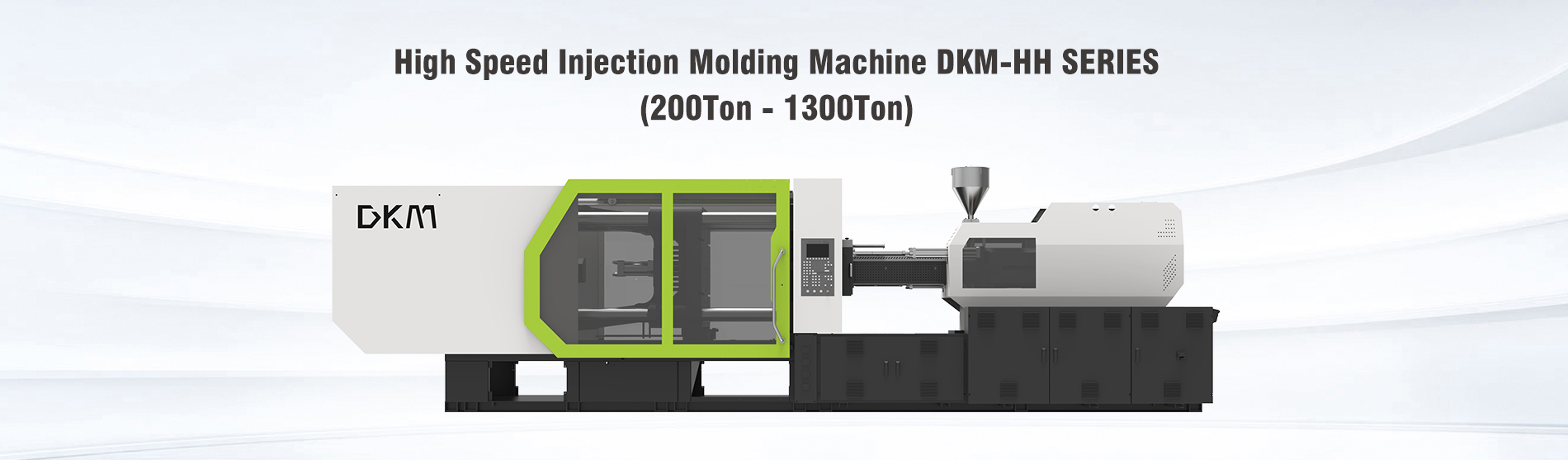

The DKM Fast Speed Molding Machine series, ranging from 200 tons to 1300 tons, offers a range of outstanding features that set them apart in the industry. These machines are designed to deliver exceptional performance, precision, and reliability, ensuring optimal results for your molding needs. With lightning-fast response times, tight tolerance control, and robust construction, it enable rapid production, high-quality output, and uninterrupted operation. Additionally, their customizable options allow for flexibility, empowering you to adapt to changing market demands. Experience the power of DKM and elevate your injection molding process to new levels of efficiency and success.

When it comes to operating the Molding Machine series (ranging from 200 tons to 1300 tons), Dakumar ("DKM") has engineered these machines to excel in the field of plastic injection molding. The performance and efficiency of these cutting-edge machines are astounding throughout the production cycle. With their advanced technology and precise control systems, DKM Fast Speed machines ensure smooth and seamless operation. From the initial mold setup to the final ejection of the perfectly formed plastic parts, these machines exhibit exceptional speed, accuracy, and reliability. Whether you are producing intricate components or large-scale productions, the Machines provide the reliability and precision required for successful plastic molding.

When utilizing the DKM Fast Speed Injection Molding Machine series (ranging from 200 tons to 1300 tons), it is important to adhere to the following guidelines for optimal operation.

Before commencing any production, carefully inspect the machine and ensure all components are in proper working condition. Verify for any damage or irregularities that could impair performance. Follow the manufacturer's instructions for machine setup and configuration.

Choose the appropriate plastic material for your molding process. Consider factors such as material compatibility, desired properties of the final product, and processing requirements. Consult material datasheets and conduct thorough testing to ensure optimal results.

Design a mold that meets your specific requirements. Pay attention to factors such as part geometry, gating, and cooling channels. Optimize the mold design to minimize cycle times and reduce production costs. Ensure the mold is properly cleaned, maintained, and aligned with the machine before installation.

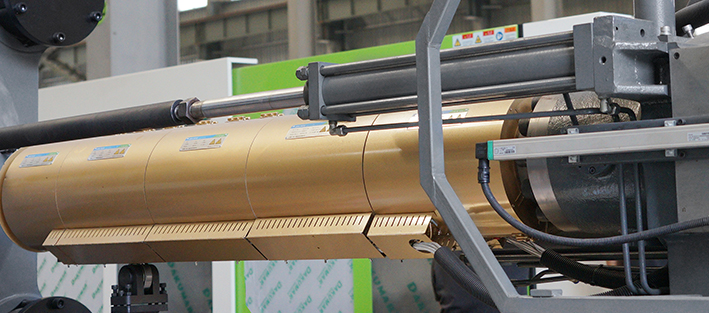

Adjust the machine parameters according to the specific material and mold requirements. Injection speed, temperature, pressure, and cooling duration are some of these variables. Fine-tune these settings to achieve the desired part quality and optimize cycle times. Regularly monitor and adjust the settings as needed during production.

always Prioritize safety during machine operation. Follow proper safety protocols, such as wearing appropriate personal protective equipment (PPE) and ensuring all safety guards are in place. Train operators in safe machine handling, emergency procedures, and proper use of tools and equipment.

Regularly maintain the machine to keep it in optimal working condition. Follow the manufacturer's recommended maintenance schedule, including lubrication, cleaning, and inspection of key components. Promptly address any issues or malfunctions by troubleshooting or seeking assistance from qualified technicians.

Continuously monitor and analyze the production process to identify areas for improvement. Collect data on key performance indicators, such as cycle time, scrap rate, and energy consumption. Implement process optimization strategies to enhance efficiency, reduce waste, and increase overall productivity.

When it comes to the advantages of utilizing the Machine series (ranging from 200 tons to 1300 tons), there are numerous benefits that set these machines apart. Here is a overview of the advantages of using DKM Fast Molding Machines:

Please contact us directly and we will develop the right injection molding machine solution for you according to your needs.

When considering the Fast Molding Machine series, which ranges from 200 tons to 1300 tons, there are a few key points to know about these machines:

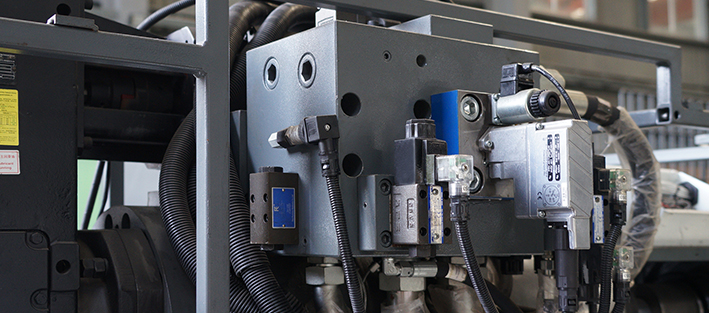

The machines are specifically designed for rapid production. They incorporate advanced servo motor technology and optimized hydraulic systems to achieve fast mold opening and closing cycles. This results in reduced cycle times and increased production output, enhancing overall efficiency.

These machines are engineered to deliver tight tolerance control, ensuring precise and consistent molding results. The advanced control systems and robust construction contribute to high-quality plastic parts with repeatability, meeting the strictest requirements and specifications.

The Fast Speed series offers a range of customization options to suit various production needs. This includes multiple injection unit configurations and flexible clamping mechanisms, allowing manufacturers to tailor the machines to their specific requirements. The versatility of these machines enables versatility in product design and production flexibility.

Robust Construction for Longevity

High-Quality Components for Reliable Performance

Built for Continuous Operation and Minimal Downtime

Durability to Withstand Demanding Production Environments.

When considering the purchase of a plastic injection molding machine, there are several compelling reasons to consider buying DKM. Here are some headings highlighting the key factors that make this company a worthwhile choice:

DKM offers competitive pricing for the DKM-HH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

In conclusion, DKM is a compelling choice when it comes to purchasing a plastic molding machine. With its superior performance, efficiency, and advanced technology, DKM machines offer rapid production, tight tolerance control, and precise results. The reliable and durable construction ensures long-lasting operation with minimal downtime. The versatility and customization options cater to diverse production needs, allowing for flexibility in meeting specific requirements. Our machines are designed with energy efficiency in mind, contributing to sustainable manufacturing practices and cost savings. The comprehensive support and service provided by DKM ensure a seamless experience, from installation to ongoing technical assistance. With its established reputation, industry experience, and value for investment, DKM stands out as a trusted name in the injection molding industry. Consider investing to elevate your production capabilities and achieve outstanding results in plastic injection molding.

Contact us to help you choose the suitable machine and complete injection molding solutions.