The DKM-EH series of electro-hydraulic hybrid injection molding machines is now in mass production after two years of stability testing. Through the combination of high drive servo power system and intelligent control system, the injection system is realized with closed-loop control, which makes the repeat positioning accuracy within 0.01mm. This outstanding feature makes the EH series injection molding machine can be widely used in the molding process of medical devices, precision IT parts and other devices with high precision requirements.

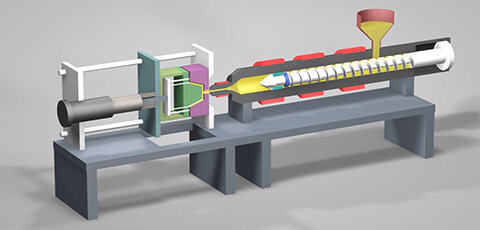

The DKM-EH series is an injection molding machine designed for products with high precision requirements. With a clamping force range of 130Ton - 450Ton, this series of machines is the best choice for the production of fine precision products. An important feature of DKM-EH series is its servo all-electric injection system, which is controlled by high-precision screw motion, making the injection displacement precise, and the high-speed injection makes the molded products stress-equalized without deformation, which makes it an excellent choice for the injection of precision medical devices.

To further enhance performance, the DKM-EH series machines have high-performance machine setups such as an intuitive HMI interface, remote monitoring system, high-speed response drives and high-strength moldboards. These features make the machines easy to operate and maintain, while increasing machine strength, speeding up productivity and reducing downtime. The DKM-EH series injection molding machine is versatile. It can be used for fine precision products and the machine is also compatible with a wide range of materials such as PP, PE, PS and PET.

Whether you are a beginner or an experienced user, you can follow the following steps to achieve the best results.

Before you start the machine, plesae carefully inspect the machine and ensure all components are in proper working condition. Follow the manufacturer's instructions for machine setup and configuration. Check for damage or abnormalities that may affect performance.

Select the appropriate plastic material for the molding process. Consider factors such as material compatibility, expected performance of the end product, and processing requirements. Consult material data sheets and conduct thorough testing to ensure optimal results.

Select the proper clean mold for the desired product and carefully install the mold onto the machine platen according to the specific instructions. Ensure that the mold is securely fastened and properly aligned with the machine's clamping mechanism.

Machine parameters are adjusted based on specific material and mold requirements. Injection speed, temperature, pressure and cooling time are some of these variables. Adjust these settings as required and monitor them regularly during production and adjust the settings as needed to achieve the best possible injection molding results.

Always prioritize personal safety during machine operation. Strictly follow proper safety procedures and ensure that all safety guards are in place. Providing training for operators in the safe operation of the machine, emergency procedures and the correct use of tools and equipment.

Maintain your machine regularly to keep it in optimal working condition. Follow the manufacturer's recommended maintenance schedule, which includes lubricating, cleaning and inspecting critical components. When in doubt, contact the merchant timely.

Continuously monitor and analyze production processes to reduce waste and improve overall production efficiency by implementing process optimization. DKM will always be there for supporting you.

Please contact us directly and we will develop the right injection molding machine solution for you according to your needs.

If you are considering using the DKM-EH series of high-speed injection molding machines, there are several important factors to remember. Here are some key things you need to know about this machine series:

The DKM-EH series incorporated advanced all-electric injection technology, ensuring the best injection precision.

Facilitates fast injection speeds, leading to shorter cycle times, increased productivity, and improved production output. Enhances efficiency and optimizes overall production time.

Equipped with an intuitive interface for easy parameter setting, monitoring, and adjustments. Offers live data visualization, diagnostic features, and troubleshooting guidance for streamlined operation and maintenance.

Ensures stability, durability, and minimized vibrations during operation, resulting in enhanced accuracy and product quality. Provides a reliable solution for large-scale manufacturing requirements.

The EH series are widely used in the components molding with high precision requirements such as medical devices and precision IT parts.

Incorporates advanced energy-saving technologies and servo motor systems to reduce power consumption and lower production costs. minimises environmental effect while promoting sustainable manufacturing.

DKM offers competitive pricing for the DKM-EH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

Dakumar's DKM-EH series is a top-of-the-range injection moulding machine designed for fine precision parts. With its all-electric injection technology and advanced features, it provides customers with high precision and reliability, while dramatically increasing the ability to produce efficiently and with superior product quality.

Contact us to help you choose the suitable machine and complete injection molding solutions.