Welcome to Chinaplas 2024 advance notice page for DKM! Get ready to immerse yourself in the latest innovations and cutting-edge injection molding technologies at our Chinaplas 2024 booth 5.1D72. Here's a sneak peek at what we'll be showcasing:

At ChinaPlas2024, we will be showcasing our latest generation of injection molding equipment, spanning across four major industries: PET, thin-wall packaging, industrial packaging, and medical.DKM aims to assist customers in overcoming industry bottlenecks, addressing challenges in the injection molding sector, and enabling them to create greater value.

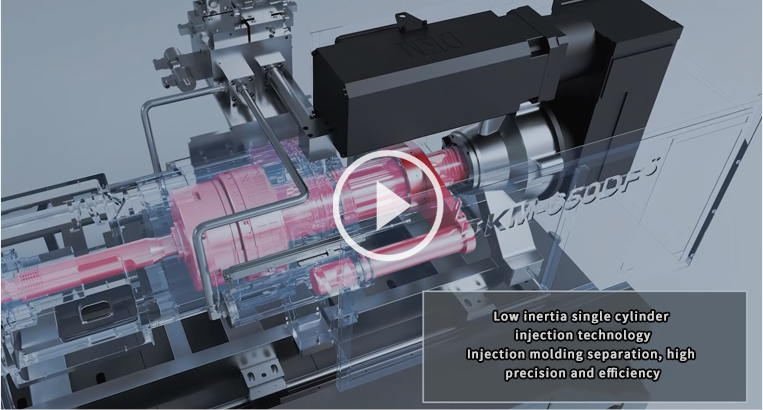

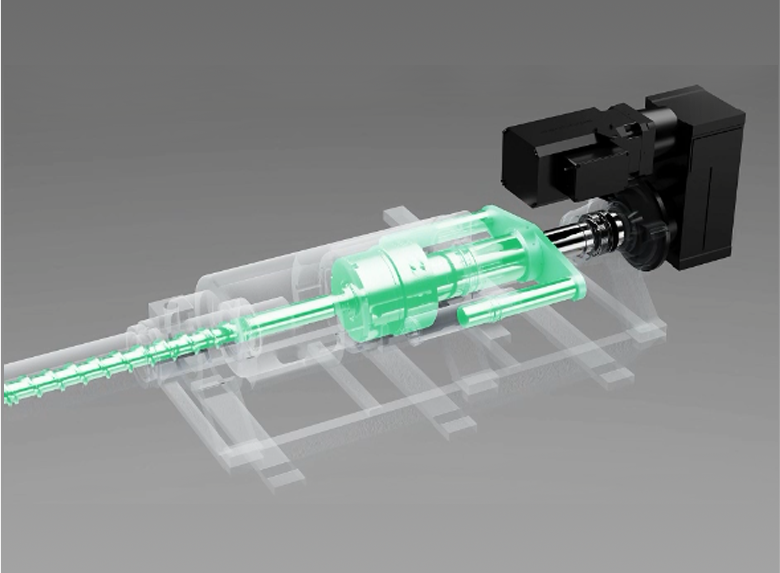

The low inertia high precision injection molding technology is the innovative culmination of five years of dedicated research by DKM. It enhances injection response speed and repetition accuracy while achieving energy savings of up to 30%. DKM's technical innovation in the design of the injection platform truly separates the "injection" and "molding" actions, reducing energy consumption during the injection process by keeping the plasticization system stationary. This innovation not only reduces energy consumption but also meets the demand for improved repeatability and response speed in injection molding machines.

We continuously break through industry technological bottlenecks through ongoing innovation and product upgrades. By offering high-performance, efficient, and intelligent injection molding equipment along with customized services, we can better meet customers' needs, help them reduce costs, increase efficiency, and enable them to create greater value.

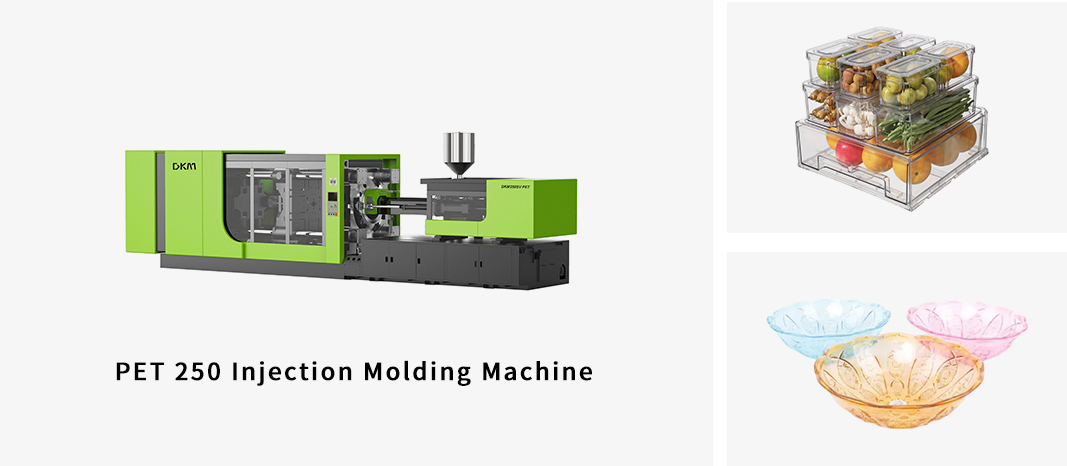

Comprehensively addresses PET plasticization and gate whitening issues.

The new generation PET injection molding machine, integrating innovative low inertia technology, achieves a dual enhancement in efficiency and quality.

Utilizing PET-specific extended screw design, the PET material undergoes large-scale plasticization with low shear and high blending, ensuring high plasticization efficiency.

The brand-new high-power integrated infrared heating ring provides precise temperature control, coupled with the needle valve flow channel system of the fruit tray mold, ensuring precise temperature control and producing PET products with high clarity and transparency without whitening.

Applying "low inertia high precision injection molding machine technology" to PET injection molding machines, ensuring high precision, speed, and stability. With enhanced stability, injection response speed is doubled, and injection repetition accuracy reaches 2‰.

With enhanced computing power, performance is significantly improved. Equipped with a visual touchscreen interface, operations are easy and efficient with just a touch.

The application of low inertia technology reduces the inertia of the injection molding machine, resulting in lower heat generation and higher efficiency. Energy consumption is reduced by 15%-20%, aiding customers in cost reduction and efficiency enhancement.