The global chair market is expected to reach $38 billion by 2025 as more and more people choose to work from home due to the COVID-19 pandemic, and the global demand for chairs is increasing.

At this point, the advantage of choosing a good supplier appears.

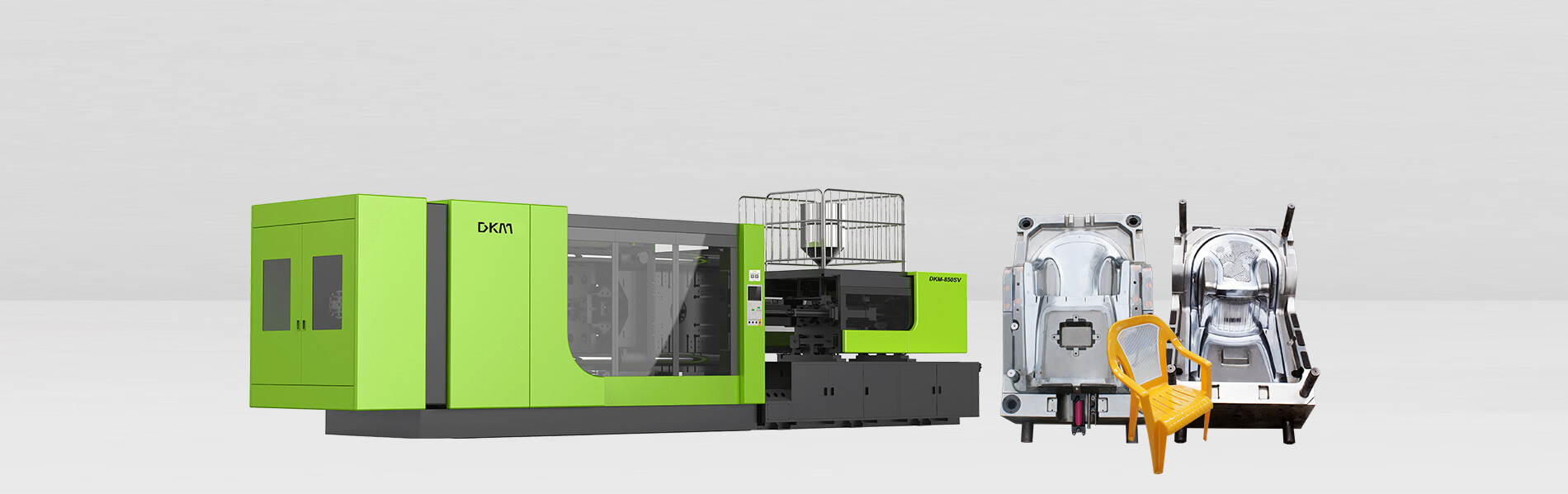

DKM is committed to providing customers with the whole chair production line service, from the mold to the machine to the auxiliary machine, all provided by us,which can help you set up a plastic chair making factory in the shorest time.

With advanced design concept, diversified product system, perfect after-sales service to provide customers with new experience.

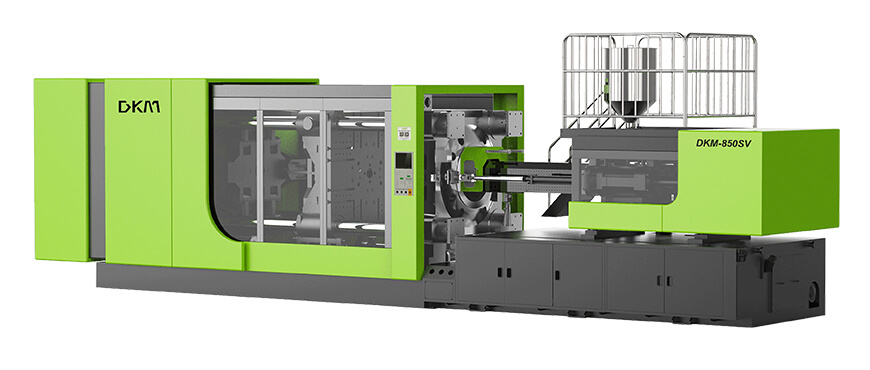

High energy saving - servo motor control system only delivers hydraulic oil as it is needed for various functions, which prevents unnecessary generation of heat and substantially reduces oil cooling requirements.

Long working life - high efficiency, lower oil temperature, making oil tank much smaller and service life of hydraulic oil and elements much longer.

Molding stability - injection carriage linear guide with high precision and speed for injection, respond ability is greatly improved due to energy saving closed-loop control.

Quite operation - silent high efficiency hydraulic system, runs at a much lower noise level, particularly in low speed applications.

Clamping force - from 800 KN to 40000 KN

Ready European standard connector for robot.

Suitable for industrial containers, chairs and crates, home appliances, automotive parts…

We can offer customized energy saving plastic injection machine according to your special requirements.

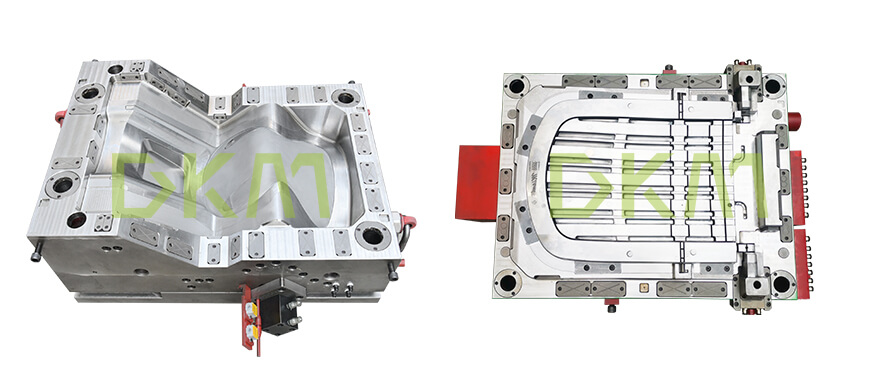

1. There are a sufficient number of waterway designs for the product surface. According to customer requirements, beryllium copper inserts are used in places with more ribs at the seat cushion to ensure the overall cooling effect of the mold, reduce the molding cycle and improve production efficiency.

2. The chair flower panel adopts the processing technology of Beijing Carving, which makes the molded product surface more three-dimensional and beautiful.

3. The interchange plate has a mature structural design, which is more stable and fast during replacement.

4. Using the large nozzle hot runner independently developed by the company, compared with the cold runner, the pouring pressure is reduced, the weight of the cold runner is reduced, and it can be produced without lengthening the nozzle.

5. The sealing surface of the product is treated with a special process to improve the hardness of the raw material, reduce the flash problem caused by the wear of the parting surface in continuous production, and improve the life of the mold

6. Using high-speed milling and precision EDM processing, one-time assembly and matching of molds are successful, and the quality of molds is improved.

1. High quality system solutions, turnkey solutions and engineering solutions, rich engineering experience in the field of furniture and equipment.

2. Synchronous optimization of slider core pulling structure, rapid response of machine oil circuit, stable production and saving time of core pulling.

3. The ejection of the mold is synchronized with the injection molding machine and the robot, which greatly saves the cycle time.

4. The production line equipment is selected by the company's professional and technical personnel, which can maximize the value of customer's consumption and realize the optimal production capacity and benefit.

5. Time cost is the biggest cost, strict delivery time control is implemented, and the whole production line can achieve mass production within 5 months.

6. The robot device can realize the intelligent assembly line operation of chair products, greatly saving the production cost.

Take a look at DKM Plastic Chair Making Line! Equipped with DKM-850SV, this production line highly improves production efficiency.

As our brand name says--Delivery the Key of Molding, DKM devotes to providing turnkey solution for you.