DKM take along injection molding machine with innovative solutions at ChinaPlas.

On April 17, 2023, CHINAPLAS 2023 was officially opened in Shenzhen. 3900 international exhibitors gathered here to explore, exchange and share information and development trends of the industry, to help the industry cope with the upgrading of key technologies in the new era and enhance their own competitive strength.

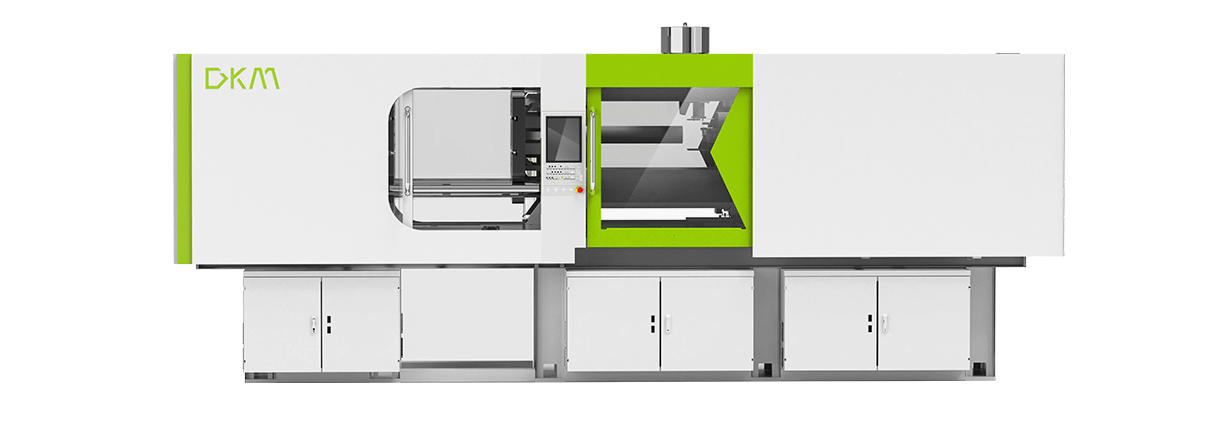

After three years of recuperation, DKM is riveting full strength to shine at ChinaPlas! DKM has presented three solutions in Shenzhen exhibition. The low inertia injection molding machine is a new independently researched and developed model of DKM. The advanced technology first officially displayed to the public has impressed visitors around the world.

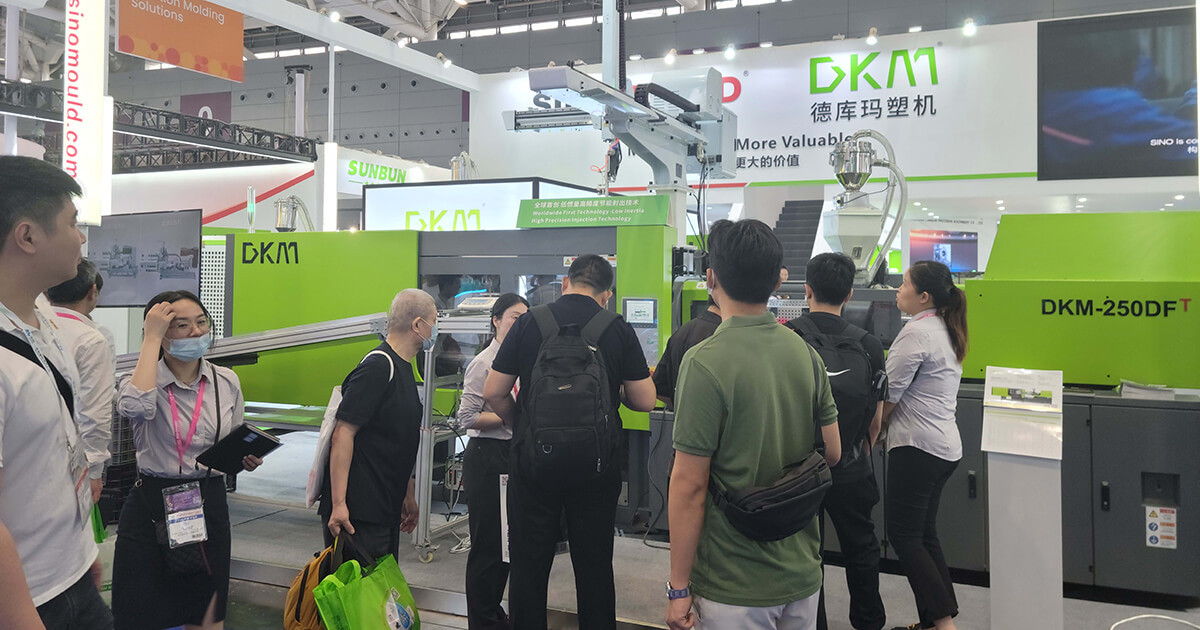

On the first day of the exhibition, DKM with the world's first low inertia injection molding machine and intelligent production solutions, has attracted widespread attention. A large number of business visitors have been attracted to stop to watch and had in-depth communications with our sales engineers. There was a surge of popularity in DKM booth.

At the exhibition site, we also show the injection accuracy of the new low inertia injection molding machine in real time to visualize the high-precision data and more comprehensively display the highlights of the new low inertia injection molding machine, At the same time, DKM sales engineers were introducing equipment and program details to customers providing with detailed and enthusiastic consulting services.

Separate storage servo motor from the moving plate of injection unit to reduce inertia in injection molding and control products repeated accuracy within ±1.88‰.

Equip spline transmission mechanism to reduce the transmission force of screw rotation and improve the injection molding response speed.

Low heat, high efficiency, large overload capacity and fast response, reducing energy consumption by 15%-20% compared with standard models.

Adopt pure two platen structure, electric ejector cylinder and separate mould platen to avoid oil pollution and ensure clean production.

Adopt linear guide for improved moving accuracy, decreased friction and keeping clamping unit clean.

Adopt separate self-adjusting mould platen to save more than 20% of the clamping force comparing to standard injection molding machine and avoid flash.

PET special screw with large L/D ratio allows higher plasticization capacity and more stable plasticizing process.

Extend machine frame and enlarge space between tie bars provides more space for mold opening and ejection and fits special dimension PET preform mould.

High precision single cylinder injection system, suitable for PET molding lines, with low-inertia and high response speed.

High injection speed and high-response servo-hydraulic system realize mould opening, closing and charging at the same time.

Adopt high precision cylinder injection system realize high speed, low inertia and fast response.

DKM new low inertia injection molding machine with its three advantages of high precision, high speed and high energy saving became popular player on the first day of the exhibition. Energy saving 15%-20% compared with traditional servo machine, injection repeat accuracy ±1.8‰ and 50% faster response.

In addition to the new low inertia injection molding machine debut, DKM also exhibited two models of DKM injection molding machines - DKM-MX Clean Injection Molding Machine and DKM-450 PET Injection Molding Machine and complete injection molding solutions. MX Clean Injection Molding Machine has demonstrated the production of pipette tips, which reflecting the further upgrade and innovation of DKM in the field of clean medical injection molding. The 450 PET Injection Molding Machine demonstrated the intelligent manufacturing system of bottle preform on site, showing the efficient application of DKM in the packaging industry.

This exhibition will last for three days until April 20th. We are at the 9J31/9J33 Sino/DKM booth. Welcome to your presence and look forward to meeting you!

Medical equipment widely used in hospital, laboratory and other medical facility. As a necessary part of medical equipment injection molding, medical injection molding machines should keep clean in injection molding process to ensure products having no pollution.

Usually used in experiments and therapy, medical equipment also has high requirements for accuracy. Medical injection molding machine should be operated precisely to reduce the error and improve the accuracy.

Traditional injection molding machines are driven by hydraulic motors and are easy to cause oil pollution during injection molding process. Considering the strict requirements of medical devices production, DKM MX Medical Injection Molding Machine adopt all electric injection unit design to avoid oil leakage and keep clean in injection molding.

Plastic injection molding offers great versatility in terms of design possibilities. The ability to mold complex shapes, incorporate intricate details, and utilize various materials allows manufacturers to create customized components that meet specific requirements.

With rapid cycle times, plastic injection molding enables fast production rates. The quick cooling and ejection process, combined with high-speed injection capabilities, result in shorter lead times and faster time-to-market for products.

Plastic injection molding supports a wide range of materials, including thermoplastics and thermosetting plastics. Manufacturers can choose materials with different properties, such as strength, flexibility, or heat resistance, to suit the intended application.