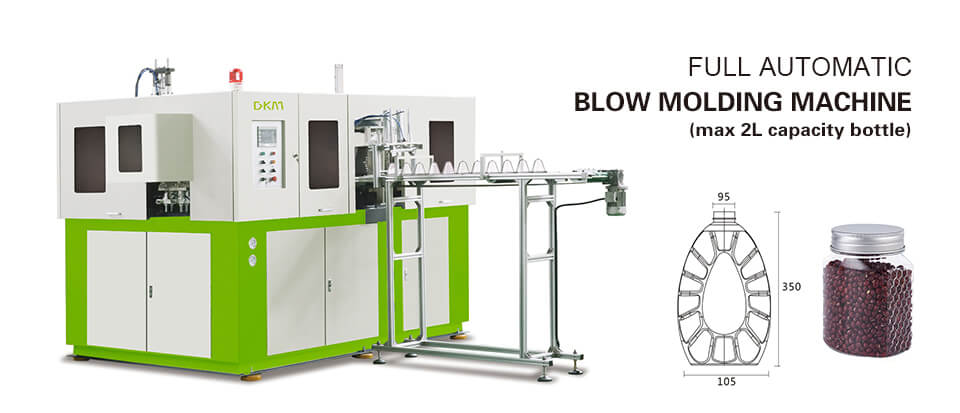

DAKUMAR offers quality blowing molding machine meeting different production capacity. Our machines have been exported to worldwide as features of high efficiency, low power consumption, convenient operation and simple maintenance.

The blowing machine SINO produced has the following advantages:

Simple structure in liner type, easy in installation and maintenance.

Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts

Running in a high automatization and intellectualization, no pollution.

Apply a linker to connect with the air conveyor, which can directly inline with filling machine.

Stretch blow molding, save much more air consumption with high capacity and long service life.

High quality muffler, and safety protecting gate, guarantee operators safe.

Reasonable design, full automatic control, save power and Labor, adopting high quality components.

Infrared oven heater adopts the quartz lamp to heat the PET tube.

Fully automatic process with low investment, high efficiency, quick and safe operation, easy for trouble-shooting, maintenance and other benefit.

This model could blow normal PET bottles as well as wide-mouth bottles.

Advantages:preforms feeded by hand and bottles heated and blowed automatically, no techinical requirement from this worker, hourly capavity from 1000 to 4000pcs, lower cost than usual automatic machines while enjoying stable performance

Full-Automatic Blowing Machine -- Large Capacity Bottles: Max. 20L