PET Bottle Production Line

Striving for excellence

Maximizing your output

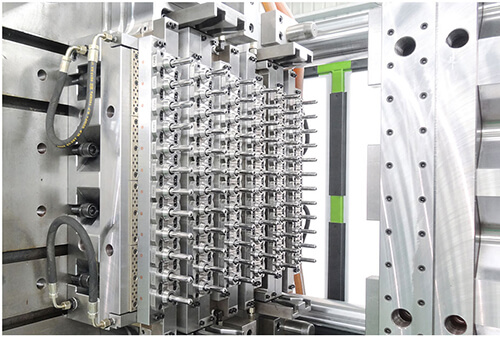

PET bottle production line included PET preform injection molding system,

PET bottle blow moulding system, water bottle filling system and packaging system.

Preform Production

Filling Production

Packaging Solution

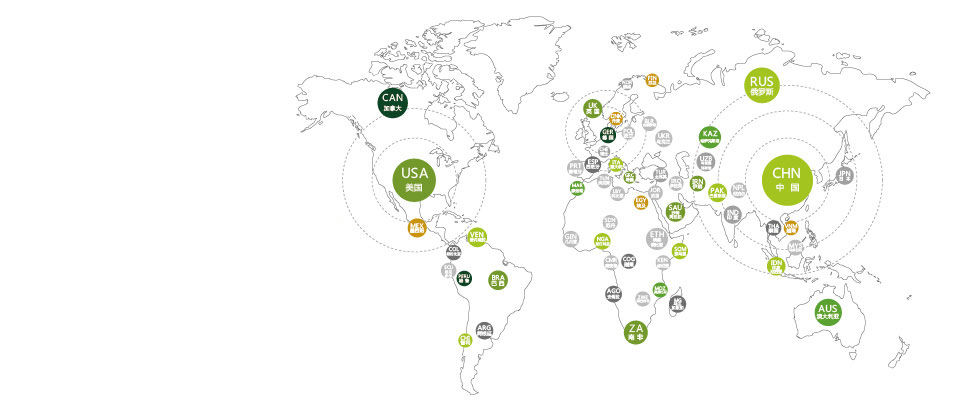

Why DAKUMAR – One Stop Bottle Molding Solution

That's the benefit you get from us!