DKM has around 20 years of experience in PET injection molding machines. Since DKM establishment, DKM's PET injection molding machines have been updated and iterated to the 3rd generation. DKM-PET III has the features:Rapid plastic melting, rapid mixing, high-speed injection, high-precision injection.Among the different demand of plastic injection molding products, PET injection moulding machines have distinguished themselves as crucial tools for creating high-quality plastic components. Due to their remarkable performance, accuracy, and versatility, these machines—whose sizes range from 250-650Ton —are highly recognized across a variety of industries of liquid packaging and household parts.

Modern production technologies are driving the transformational phase that the plastics sector is currently going through. The machine for PET injection molding is one such innovation. With tonnage capabilities ranging from 250 tonnes to 650 tonnes, these innovative machines set the bar for innovation and enable producers to create high-quality plastic components with extraordinary accuracy and efficacy. PET injection molding machines are becoming essential tools for many industries thanks to their exceptional capabilities and wide range of uses.

PET injection molding machine is designed for the characteristics of PET materials, suitable for all kinds of plastic products using PET as raw materials, including but not limited to PET bottles, PET storage boxes, etc.

DKM PET injection molding machine in addition to the injection performance of the upgrade, but also pay attention to the human design of the machine.

It features user-friendly interfaces with intuitive control panels and touchscreens, enhancing usability and productivity. The machines are robustly constructed with durable materials and components, ensuring longevity, reliability, and consistent performance even under heavy production loads.

Furthermore, safety measures such as emergency stop buttons, safety interlocks, and protective barriers are incorporated, providing a secure working environment for operators.

PET injection molding machines in the range of 250 tons to 650 tons exhibit remarkable operational capabilities that streamline the plastic manufacturing process. These machines boast a user-friendly interface that allows operators to easily set and adjust molding parameters, ensuring precise control over the injection process. With fast cycle times and high-speed injection capabilities, they enable manufacturers to achieve efficient production rates without compromising on quality. The robust construction of these machines ensures stability and durability during operation, even under heavy workloads. Additionally, advanced safety measures and protective features ensure a secure working environment for operators. Whether it's producing PET bottles, containers.These machines deliver consistent performance, exceptional precision, and reliable operation, making them indispensable assets for businesses in the plastic manufacturing industry.

Operating a PET injection molding machine (250Ton - 650Ton) requires a systematic approach to ensure smooth and efficient production. Here is a step-by-step instruction sheet to assist you in successfully completing the process.

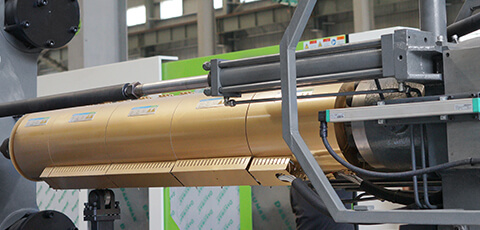

With electrical pre plastic charging system, DKM-PET Injection Molding Machine realize fast and precise injection molding.

Start by looking over the machine for any obvious flaws or damage. Check the mold and ensure it is clean and properly installed. Make sure the required raw materials, such as PET resin, are available and stored in a suitable condition.

Power on the PET injection molding machine and allow it to warm up according to the manufacturer's instructions. Set the temperature and pressure settings based on the specific requirements of the PET material being used. Adjust the mold clamping force, ejection system, and other machine parameters as necessary.

Load the PET resin into the hopper of the machine, ensuring that it is free from moisture or contaminants. Adjust the drying and dehumidifying settings if required, to maintain the material's optimal condition.

Set the injection speed, pressure, and time according to the desired specifications for the plastic part. Activate the injection unit and monitor the machine closely during the injection phase. Ensure that the molten PET material fills the mold cavity uniformly and accurately.

Allow sufficient time for the injected plastic to cool and solidify within the mold. Maintain the appropriate cooling temperature and time, as specified by the resin manufacturer, to ensure proper part formation and minimize defects.

Once the plastic part has cooled and solidified, open the mold using the machine's controls. Activate the ejection system to release the part from the mold. Ensure that the ejection pins or mechanisms do not damage the part during removal.

Carefully examine the produced parts for any defects, such as warping, shrinkage, or surface imperfections. Use measuring tools and gauges to verify the dimensions and specifications of the parts. Conduct quality control tests, if required, to ensure the parts meet the desired standards.

If everything is in order, repeat the process for subsequent cycles. Adjust the machine settings, as necessary, to optimize production efficiency and maintain consistent part quality.

Regularly clean and maintain the PET plastic injection molding machine to prolong its lifespan and prevent malfunctions. Remove any excess material or residue from the machine and its components. Lubricate moving parts, check for wear and tear, and address any issues promptly.

There are several reasons to choose this injection molding machine. However, some of the most considered ones are:

Please contact us directly and we will develop the right injection molding machine solution for you according to your needs.

A high-speed injection molding machine is specifically engineered to enhance production efficiency by minimizing cycle times. These machines integrate cutting-edge hydraulic and control systems, enabling swift injection and swift movements for mold opening and closing. As a result, the overall production cycles are significantly shortened. Industries that require rapid production rates, such as packaging, consumer goods, and automotive manufacturing, often employ high-speed machines to meet their needs effectively.

Two platen molding machines are known for their structural stability and versatility. Unlike traditional machines with three plates, two platen machines have a simplified design, consisting of a stationary platen and a moving platen. This configuration ensures better mold alignment, improved clamp force distribution, and enhanced precision during the injection process. Two platen machines are favored for their ability to handle larger molds and accommodate various injection molding applications.

DKM-high speed machines are designed with advanced technology and components to enable fast injection and mold movements. High-speed machines are suitable for applications where quick production cycles and high productivity are essential.

An extra-large injection molding machine is built to handle large-sized plastic parts or components. These machines have sturdy structures, increased mold clamping forces, and extended daylight spaces to accommodate larger molds. They are frequently utilised in sectors including automotive, aerospace, and industrial manufacture where it is necessary to produce huge plastic parts.

Low inertia injection molding machines are designed with lightweight moving components to minimize inertia and improve the machine's responsiveness. This design feature allows for faster acceleration and deceleration of the machine's movements, leading to shorter cycle times and enhanced productivity. Low inertia machines are commonly utilized in high-speed applications where rapid injection and mold movements are critical.

DKM offers competitive pricing for the DKM-DH series machines, making them an affordable option for businesses of all sizes. Additionally, the high-speed and high-efficiency performance of the injection molding machine can reduce production costs and improve profitability over time.

In conclusion, the DKM machine stands as an exceptional choice for manufacturers in need of a reliable, efficient, and versatile solution. With its robust construction, technology, and user-friendly interface, it offers precise control, enhanced repeatability, and high-quality production. Its energy-saving features contribute to cost savings and sustainability efforts. The machine's adaptability to various applications allows for versatility and the ability to cater to different industry demands. With comprehensive after-sales support, this machine ensures a seamless experience and optimized performance. By considering this machine, manufacturers can elevate their production capabilities, achieve superior results, and make a valuable investment in their manufacturing operations.

Contact us to help you choose the suitable machine and complete injection molding solutions.